All sensors and electrical components are in some way affected by temperature and changes in temperature. This also applies to the actual bolt. In stress mechanics, an axial force (preload) applied to a bolt can be determined by measuring its elongation. However, it is not only the preload force that affects the elongation – but also the surrounding temperature and temperature changes. This is known as thermal expansion or thermal contraction.

To accurately measure the preload in a bolt the effect on electronics and the bolt elongation caused by thermal variation must be compensated for. The compensation must be accurate, repeatable and with no side effects even in environments with constantly changing temperatures, something that is a key requirement for almost all sensors.

Strainlabs Bolts & thermal effects

Strainlabs sensors measure the temperature every time a bolt preload value is measured. Each Strainlabs Bolt and its components including the PCB is calibrated to ensure that the preload value is correctly compensated for within the specified operating temperature (-30ºC to +70ºC). Strainlabs Bolts measures preload using a LED-sensor. The measurements would be inaccurate without an efficient compensation for the thermal effect of the steel and the electronical components. In Strainlabs Analytics, the temperature value is plotted on a graph just like the preload measurements.

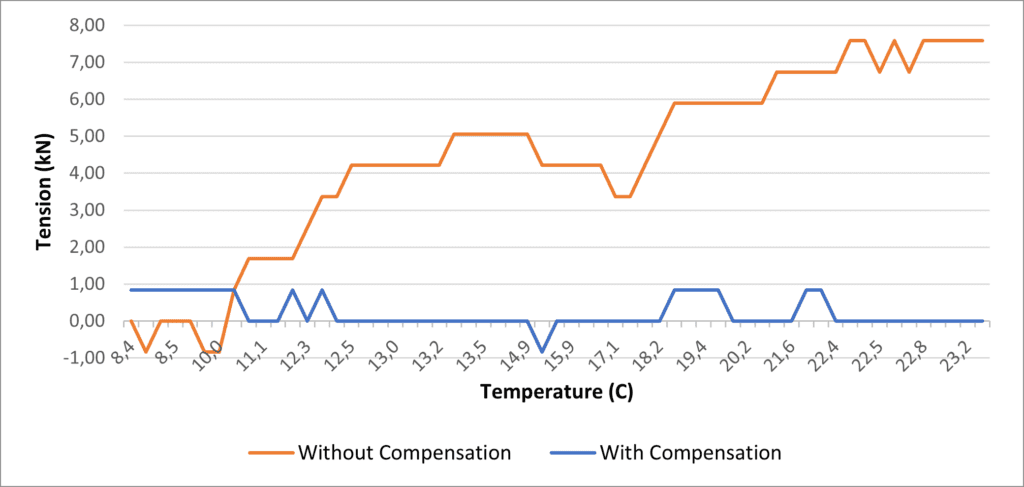

The diagram illustrates two identical Strainlabs Bolts at a constant preload but at an increasing temperature. One bolt is using Strainlabs thermal compensation features but the other one does not. In a temperature increase from approx. 8 ºC to 23 ºC the measured value for the non-compensated bolt increase by 25% relative to the bolt proof load while the compensated bolt remains at a constant value.

Advantages with thermal compensation & temperature insights

- Temperature information is required to accurately measure preload at every data point

- Insights is valuable for learnings related to thermal effects and bolt preload analysis

- Detecting condition changes (elevated temperature or temperature differences between similar machines) support condition monitoring in addition to the preload data.

- Analysing joint behaviour when clamped parts expand or contract due to temperature changes.

Strainlabs Bolts automatically adapt their preload measurement interval at low temperatures to increase battery lifetime.