How much does it cost when your production stands still? The answer depends on how much you know, before it happens. Every minute of unplanned machine stoppage costs industrial operations far more than most realize. Recent research by Siemens reveals that unplanned downtime consumes up to 11% of Fortune Global 500 companies’ revenue, translating to $1.4 trillion in annual losses across manufacturing sectors. Yet despite these significant figures, many facilities still lack comprehensive visibility into when, why, and how their equipment stops producing value.

Machine downtime represents one of manufacturing’s most significant yet underestimated challenges. While complete elimination remains impossible, understanding its various forms and implementing systematic tracking transforms downtime from an inevitable cost into actionable data that drives operational reliability and competitive advantage.

What is Machine Downtime and Why it Matters

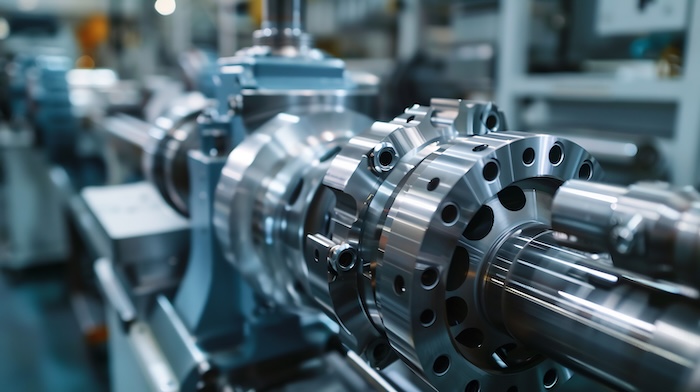

Machine downtime represents any period when production equipment fails to operate at its intended capacity or remains completely idle. This definition extends beyond obvious mechanical failures to include performance degradation, changeover delays, and maintenance activities that impact overall equipment effectiveness.

Each hour of unexpected machine downtime can cost thousands in labor, lost output, and rework. Yet many organizations still rely on reactive models rather than investing in condition-based systems that provide early warning indicators. The challenge lies not merely in identifying when machines stop, but in categorizing why they stop and measuring the true operational impact. Without this detailed understanding, facilities often address symptoms rather than root causes, perpetuating cycles of reactive maintenance and unpredictable performance.

Modern industrial operations generate tremendous complexity. A single production line may involve dozens of interconnected systems, each presenting potential failure points. When maintenance is treated as a strategic function rather than a necessary expense, organizations gain the foundation for sustainable operational excellence.

Types of Machine Downtime

Understanding the different types of machine downtime enables systematic classification that drives strategic decision-making. Each category requires specific approaches for measurement, analysis, and optimization.

Planned Downtime: Necessary but Optimizable

Planned downtime includes all scheduled interruptions to production, from routine maintenance to product changeovers. While necessary for long-term equipment health, poor execution of planned activities often extends beyond intended timeframes, creating hidden inefficiencies.

Preventive Maintenance Windows

Planned maintenance activities, component replacement, and system calibration keep equipment operating within design parameters. However, maintenance tasks that consistently exceed planned duration indicate opportunities for process standardization and technician training.

Product Changeovers and Line Reconfiguration

Manufacturing facilities producing multiple products require periodic equipment adjustments. Tracking changeover duration reveals whether standard operating procedures achieve intended efficiency levels and identifies bottlenecks in setup sequences.

Compliance and Safety Inspections

Regulatory requirements mandate periodic equipment inspections and safety system verification. While non-negotiable, optimizing inspection procedures reduces production impact without compromising compliance standards.

Calibration and Quality Verification

Precision manufacturing demands regular calibration of measuring instruments and quality control systems. Systematic tracking ensures these activities occur efficiently while maintaining accuracy requirements.

Unplanned Downtime: The Hidden Profit Killer

Unplanned downtime emerges without warning, disrupting production schedules and triggering cascading effects throughout operations. Research indicates that unplanned stops typically require 3-9 times longer resolution periods than equivalent planned activities, amplifying both direct and indirect costs.

Mechanical Failures

Component wear, bearing degradation, and system malfunctions represent the most visible forms of unplanned downtime. These failures often result from insufficient condition monitoring or delayed response to early warning indicators.

Process Deviations

Temperature fluctuations, pressure variations, and feed rate inconsistencies can halt production even when mechanical systems remain functional. These issues frequently stem from control system drift or operator procedure variations.

Supply Chain Disruptions

Material shortages, quality defects in incoming components, and logistics delays create production gaps that extend far beyond the immediate stoppage duration. Effective tracking captures both direct and indirect impacts.

Human Factors

Operator errors, inadequate training, and communication breakdowns contribute significantly to unplanned downtime. While less visible than mechanical failures, human factors often represent the most cost-effective improvement opportunities.

Advanced Downtime Classification for Strategic Decision-Making

Speed Losses and Micro-Stoppages

Modern production systems frequently experience brief interruptions that escape traditional downtime tracking. These micro-stoppages, lasting seconds to minutes, create substantial losses over time while remaining largely invisible to management systems.

Automated monitoring systems capture these brief events, revealing patterns that manual recording methods typically miss. When aggregated across shifts and production cycles, micro-stoppages often represent significant improvement opportunities.

Quality-Related Downtime

Production stoppages due to quality deviations require separate classification from mechanical failures. Quality-related downtime includes time spent investigating defects, adjusting process parameters, and reworking non-conforming products.

This category proves particularly valuable for identifying process capability issues and validating the effectiveness of quality control systems. Tracking quality-related downtime also supports continuous improvement initiatives by quantifying the operational impact of quality variations.

Changeover and Setup Efficiency

Product changeovers represent planned downtime events, but their execution efficiency varies significantly based on preparation, operator skill, and equipment condition. Detailed tracking of changeover components, setup time, trial runs, quality verification, identifies specific improvement opportunities.

Single Minute Exchange of Die (SMED) methodologies benefit tremendously from granular changeover data, enabling systematic reduction of non-value-added activities during product transitions.

The Technology Revolution in Downtime Tracking

From Manual Logs to Real-Time Monitoring

Traditional downtime tracking relies on manual operator logs, creating inherent delays and accuracy limitations. Operators focused on production restoration may forget to record brief stoppages or provide incomplete cause descriptions.

Automated systems eliminate these gaps by continuously monitoring equipment status and capturing precise start/stop timestamps. Integration with control systems provides objective data that supports root cause analysis and performance trending.

From Bolts to Business Intelligence

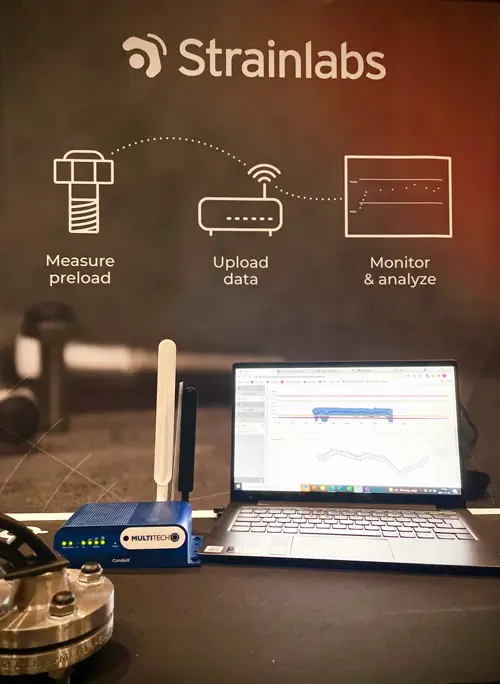

Modern machine downtime tracking extends beyond traditional mechanical monitoring to encompass comprehensive system intelligence. Advanced monitoring systems like Strainlabs’ patented LED-sensor technology transform existing equipment into intelligent assets by monitoring critical parameters such as bolt preload in machinery.

A facility using Strainlabs preload monitoring reduced inspection time by 30% while detecting potential failures weeks before traditional methods would identify issues. This approach demonstrates how the oldest machine becomes the sensor when equipped with appropriate monitoring technology, extending equipment life while providing actionable data for maintenance optimization.

Predictive Analytics and Pattern Recognition

Modern downtime tracking systems apply machine learning algorithms to identify failure patterns and predict equipment degradation. These systems analyze historical data, operational parameters, and environmental conditions to forecast maintenance requirements.

Predictive maintenance strategies reduce unplanned downtime by addressing issues before failures occur. Rather than waiting for components to fail, maintenance teams receive alerts when conditions indicate impending problems.

Building Effective Downtime Tracking Systems

Data Collection Strategy

Successful downtime tracking requires standardized categorization systems that enable meaningful analysis. Organizations must define clear criteria for each downtime category and train personnel in consistent application.

Minimum Essential Data Points:

- Equipment identification and location

- Start and stop timestamps with precision to the minute

- Downtime category and subcategory

- Operator or technician responsible

- Brief description of cause and resolution

- Parts consumed and labor hours required

Integration with Maintenance Management

Downtime tracking systems achieve maximum value when integrated with computerized maintenance management systems (CMMS). This integration enables automatic work order generation, parts inventory tracking, and maintenance cost allocation.

Real-time monitoring systems can automatically trigger maintenance requests when specific downtime patterns emerge, ensuring rapid response to emerging issues.

Performance Metrics and KPIs

Effective downtime tracking supports multiple performance metrics that guide strategic decision-making:

Machine downtime metrics like MTTR and MTBF provide objective measures of equipment reliability and maintenance effectiveness. Tracking these machine downtime indicators enables data-driven decisions that optimize both planned and unplanned maintenance activities.

Overall Equipment Effectiveness (OEE) combines availability, performance, and quality metrics into a comprehensive efficiency measure. Downtime tracking provides the availability component while supporting performance and quality analysis.

Implementing Smart Maintenance Strategies

Condition-Based Maintenance

Traditional time-based maintenance schedules often result in unnecessary component replacement or inadequate maintenance intervals. Condition-based strategies use real-time equipment data to optimize maintenance timing.

Vibration analysis, oil condition monitoring, and thermal imaging provide objective indicators of equipment health. These technologies enable maintenance decisions based on actual condition rather than arbitrary schedules.

Integration with Digital Twin Technology

Digital twin models combine real-time sensor data with physics-based simulations to predict equipment behavior under various operating conditions. These models support maintenance planning and operational optimization.

As manufacturing embraces Industry 4.0 principles, digital twins become increasingly valuable for understanding complex system interactions and optimizing overall performance.

Remote Monitoring and Diagnostics

Remote monitoring capabilities enable expert analysis of equipment condition regardless of geographic location. Specialists can diagnose problems and recommend solutions without traveling to remote facilities.

This capability proves particularly valuable for organizations operating multiple facilities or equipment in challenging locations. Remote inspections reduce travel costs while ensuring consistent expertise application.

ROI and Business Impact

Quantifying Downtime Costs

Comprehensive downtime tracking reveals the true cost of equipment stoppages, including:

- Direct production losses calculated as lost throughput multiplied by product margin

- Labor costs for idle operators and maintenance technicians

- Energy costs for equipment restart and stabilization

- Quality impacts from process interruptions

- Customer satisfaction effects from delivery delays

Investment Justification for Monitoring Systems

Modern monitoring systems typically achieve return on investment within months through reduced unplanned downtime and optimized maintenance activities. The key lies in selecting technologies that address specific operational challenges rather than implementing generic solutions.

Organizations should evaluate monitoring investments based on potential downtime reduction, maintenance cost savings, and operational reliability improvements. Comprehensive business cases consider both direct savings and strategic advantages from improved reliability.

Long-Term Strategic Value

Beyond immediate cost savings, effective downtime tracking supports strategic initiatives including:

- Capacity planning based on realistic equipment availability

- Maintenance resource optimization and training prioritization

- Equipment replacement decisions supported by objective performance data

- Supplier evaluation based on component reliability metrics

Key Takeaways: Mastering Machine Downtime Management

Before diving deeper into implementation strategies, here are the essential principles every facility should understand:

Track All Downtime Events

- Record both major machine stoppage incidents and brief micro-stoppages

- Categorize planned versus unplanned machine downtime systematically

- Capture root causes, not just symptoms

Prioritize Predictive Over Reactive

- Invest in real-time monitoring for early warning indicators

- Use condition-based maintenance strategies rather than fixed schedules

- Transform equipment into data sources through smart sensor integration

Focus on Business Impact

- Calculate true costs including labor, lost output, and downstream effects

- Use machine downtime data to drive strategic maintenance decisions

- Measure ROI of monitoring investments through reduced unplanned stops

Leverage Modern Technology

- Implement IoT solutions that turn existing assets into intelligent systems

- Consider technologies like Strainlabs’ bolt monitoring for critical applications

- Integrate monitoring data with maintenance management systems

Best Practices for Sustainable Implementation

Change Management and Training

Successful machine downtime tracking requires cultural changes that prioritize data accuracy and continuous improvement. Personnel must understand how their data contributes to organizational success and operational excellence.

Training programs should address both technical aspects of data collection and strategic importance of accurate reporting. Regular feedback sessions demonstrate how tracking data drives specific improvements.

Continuous Improvement Process

Downtime tracking systems require ongoing refinement to maintain relevance and accuracy. Regular review of categorization systems ensures they capture meaningful distinctions while remaining practical for daily use.

Monthly performance reviews should examine trending data, identify emerging patterns, and validate the effectiveness of implemented improvements. This process transforms downtime tracking from a compliance activity into a strategic tool.

Looking Forward: The Future of Downtime Management

Artificial Intelligence and Machine Learning

Advanced analytics will increasingly automate pattern recognition and failure prediction, reducing dependence on human interpretation of complex data sets. AI systems will identify subtle correlations between operating conditions and equipment degradation.

Strainlabs’ approach to bolt preload monitoring represents this evolution in action. By combining real-time sensor data with machine learning algorithms, the system identifies degradation patterns in critical fasteners before they affect equipment performance. This predictive capability transforms traditional reactive maintenance into proactive asset management.

Integration with Enterprise Systems

Future downtime tracking systems will seamlessly integrate with enterprise resource planning (ERP) systems, enabling automatic adjustment of production schedules, inventory requirements, and customer communications based on real-time equipment status.

The Internet of Bolts concept pioneered by Strainlabs exemplifies this integration potential. When every critical fastener becomes a data source, facilities gain unprecedented visibility into equipment health. This comprehensive monitoring feeds directly into maintenance management systems, creating automated workflows that optimize both planned and unplanned maintenance activities.

Autonomous Maintenance Response

Emerging technologies will enable automatic response to certain types of equipment issues, from parameter adjustments to spare parts ordering. These systems will reduce response times while ensuring consistent application of proven solutions.

Strainlabs’ patented LED-sensor technology sets the foundation for this autonomous future. By providing continuous monitoring of bolt preload conditions, the system enables predictive maintenance strategies that automatically schedule interventions before failures occur. This approach represents the new standard where equipment communicates its needs directly to maintenance systems, eliminating the guesswork that characterizes traditional approaches.

Conclusion: Transforming Downtime from Cost to Competitive Advantage

Machine downtime represents one of manufacturing’s greatest opportunities for improvement, yet many organizations barely scratch the surface of its potential impact. Comprehensive tracking and analysis transform downtime from an unavoidable cost into actionable data that drives operational excellence.

The key lies not in eliminating all downtime (an impossible goal), but in understanding its causes, minimizing its frequency, and optimizing response when it occurs. Organizations that master this balance gain substantial competitive advantages through increased equipment uptime, reduced maintenance costs, and improved operational reliability.

Success requires commitment to systematic data collection, investment in appropriate monitoring technologies, and cultivation of a culture that values continuous improvement. When maintenance is treated as a strategic function, the results extend far beyond cost reduction to encompass improved safety, enhanced customer satisfaction, and sustainable competitive positioning.

The question is not whether your operation experiences downtime, it does. The question is whether you’re capturing the insights needed to avoid failures before they happen and maximize the value of every production minute.