The importance of accuracy and precision

One of the most common questions our customers ask when considering Strainlabs System is: What is the accuracy of Strainlabs IoT sensors? Since the main purpose of Strainlabs Bolts is to measure preload, it is a logical question. However, what does accuracy really mean? In a benchmarking process, the hunt for decimals often takes the upper hand. This may be misleading because accuracy is often a misunderstood term.

Let us take you on a tour of the world of sensors and talk about accuracy and related term precision.

Understanding the terminology

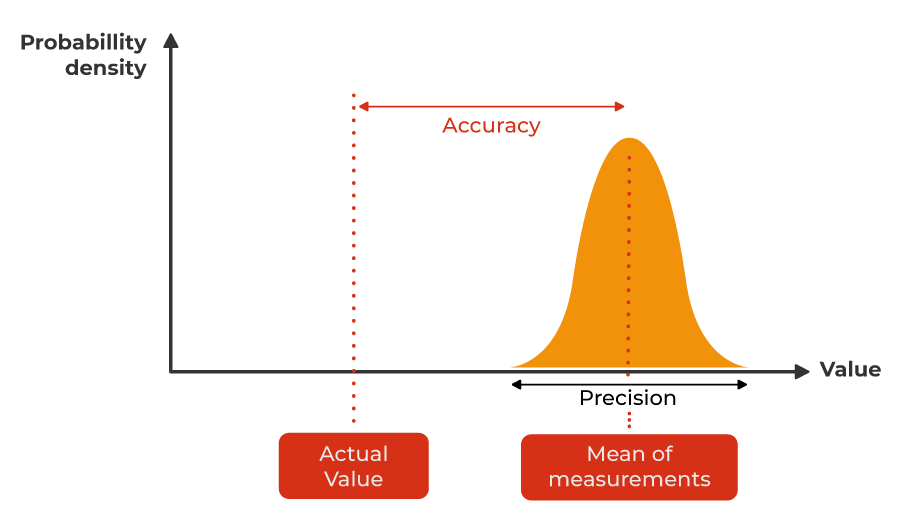

The words accuracy and precision are often interchangeably used for one another. But they are far from synonyms. Simply put, accuracy refers to how close a measurement is to the true value while precision is how close the measurements are to each other for the same value.

Accuracy points to how ‘accurate’ (or how far away) the mean of measurements is to the actual value. Precision on the other hand, is the normal distribution of measurements.

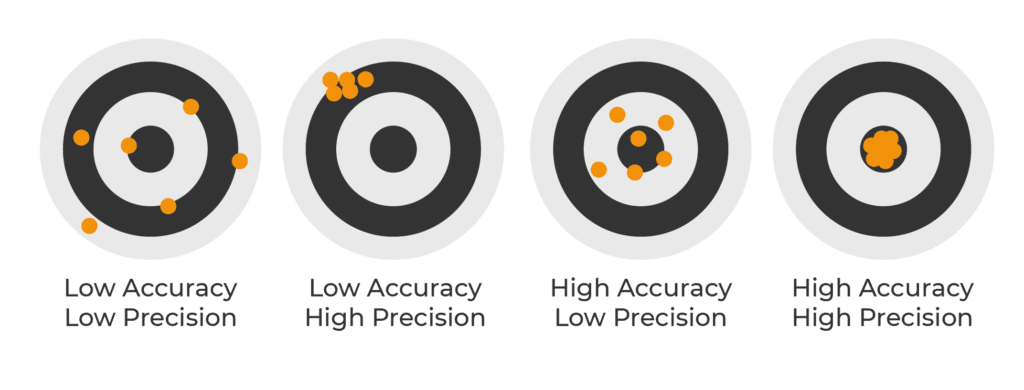

A simple way of illustrating the effects of accuracy and precision is by using a target. As can be seen, both are required to obtain reliable data.

how the resulting value would be.

Industrial value of accuracy and precision in IoT bolting

Measuring instruments are often marketed with an accuracy of e.g. ±1%. However, this percentage should be complemented with a value for the precision.

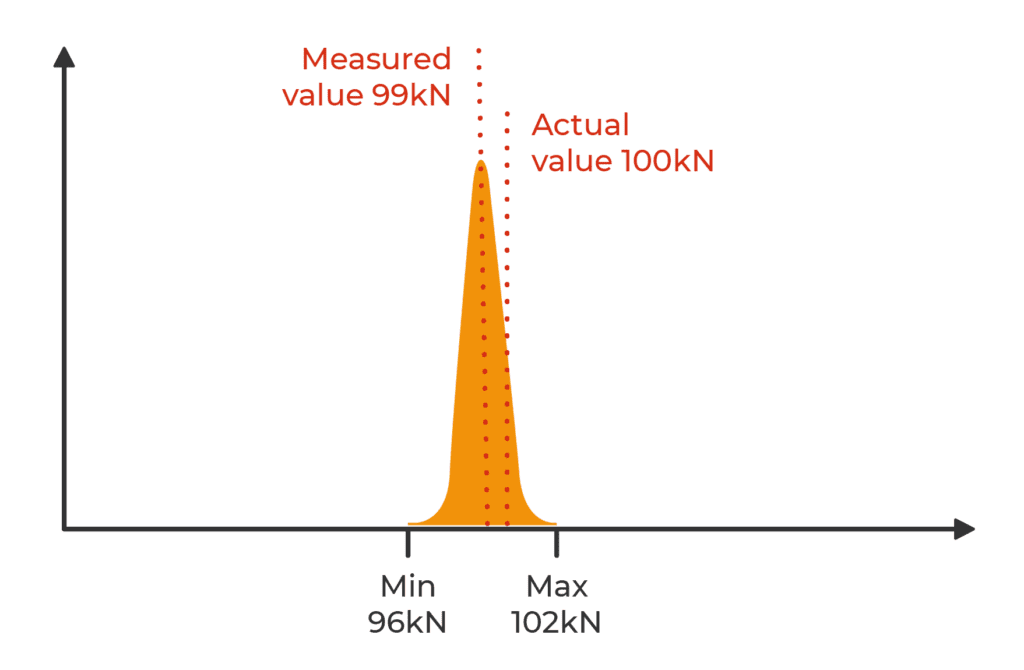

Strainlabs Bolts are calibrated to an accuracy of 99% and ± 3% precision upon delivery. Translating this into an industrial situation means that a bolt, with an actual preload of 100 kN will be measured to be 99 kN with extreme values of min 96kN and max 102 kN. In an industrial environment, this is considered very accurate and precise.

A bolt tightened to 100 kN will with Strainlabs Bolts accuracy and precision provide values ranging from 96 kN to 102 kN. This is without being a fixed installation with constant electricity supply. In addition, the sensor also measures temperature and has a completely autonomous measuring and communication process.

Strainlabs has designed the balance between accuracy, precision, battery lifetime, cost, and user-friendliness as a result of leading the digitalization of bolted joints forward. There is another flip-side – since the parameters are driven by the software a majority of the settings are adjustable to specific requirements and applications. Welcome to the Internet of Bolts!

Recommended additional reading:

- Insights section on torque vs preload

- Overview on what affects preload over time

- Strainlabs – IoT Bolts introduction and range