Strainlabs is a Swedish IndTech company turning the most common method for joining parts together, the bolt, into an IoT solution. Since last year, the system is CE-marked and available on the market for implementation into standard bolts. This spring the company exhibit at the largest maintenance exhibition in Sweden to demonstrate, live, how the system enable remote monitoring of bolted joints for predictive maintenance.

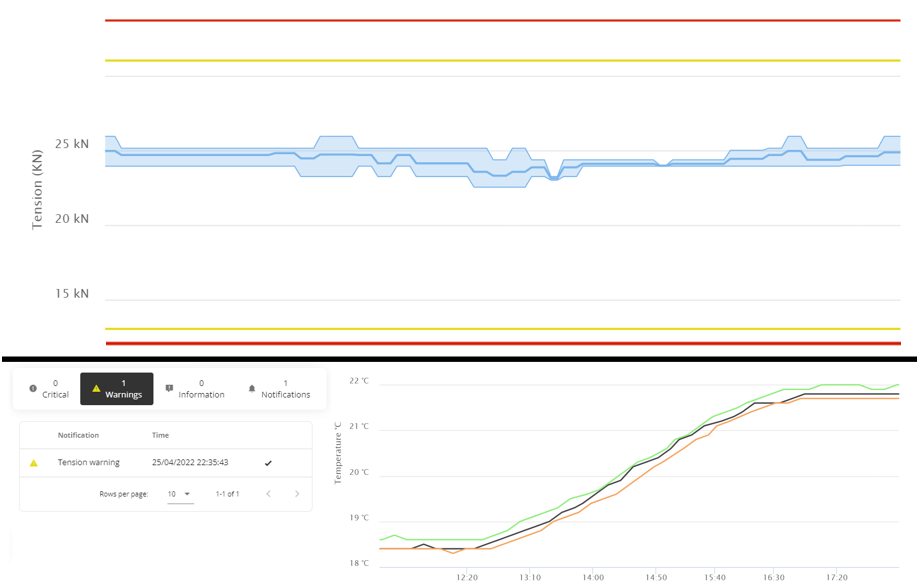

Several factors affect the achieved preload in a bolted joint – including friction, lubrication, tool accuracy and the human factor. In addition, preload also changes over time due to several natural reasons which altogether can have a major impact on safety.

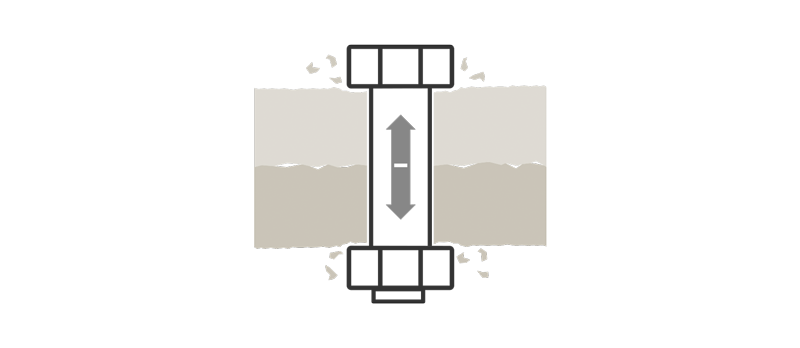

SETTLEMENTS & RELAXATION

Settlements, relaxation, and creep occur over time in all materials. The more soft materials, surfaces, coatings/paint, etc in the joint the more significant the loss of preload is over time.

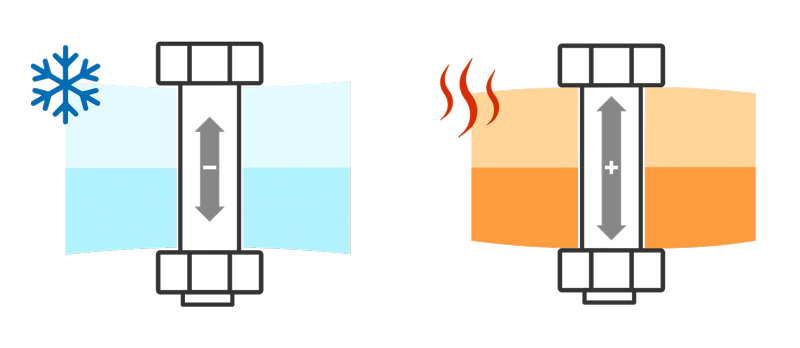

THERMAL CONTRACTION / EXPANSION

All parts in a bolted joint expand / contract due to temperature changes. Materials in a joint can also have different coefficient of expansion which may result in both increase or decrease of preload.

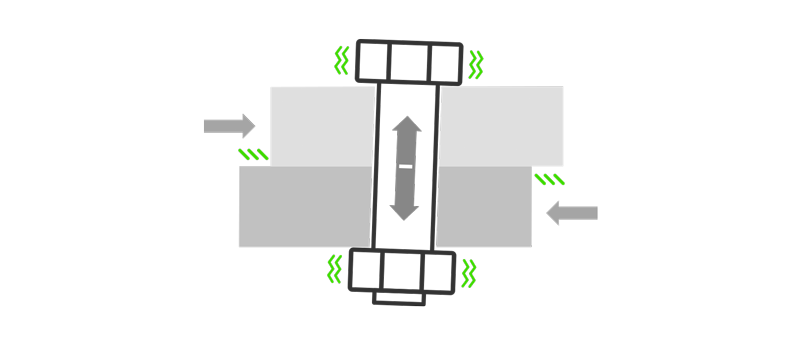

DYNAMIC LOADS & VIBRATIONS

When slipping occurs between contact surfaces move it may cause a rotation of bolts and nuts in the untightening direction, so called self-loosening. Dynamic workloads, impacts and vibration may therefore affect the preload.

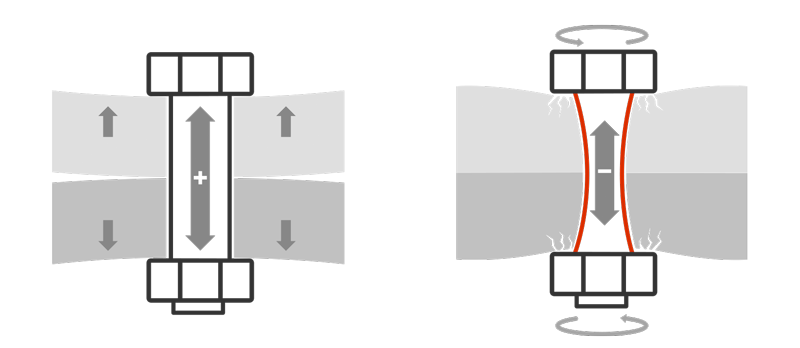

SEPARATION OF PARTS AND YIELDING

If the working load is higher than the preload in a bolted joint the parts may separate, and the joint loses its function (left illustration).

If a bolt is overtightened (i.e. ”tightened a bit extra for the sake of safety”) it can lead to yielding and/or that the joined parts are permanently deformed (right illustration).

Preload data for maintenance and insights

”It is not realistic for the industry to create exact models for the mechanical behavior over time for every bolted with the aid of laboratory environments or calculations when there are so many parameters affecting and interacting. The industry has long sought after a way to assess the safety of a bolted joint, which is actually what you do when you measure its preload” says Csaba Madru, CEO at Strainlabs with many years of experience off bolted joint technology.

Peter Isberg, Digital Lead at ABB Motion: ”Bolts are an established solution for assembly, mainly because of its high strength and its flexibility in terms of simple disassembly. Industries are today used to spending time on bolt inspections and we see great potential in this type of more advanced sensors able to give correct mechanical data during a relatively long period of time”.

Strainlabs System will be demonstrated live for the first time at a larger Swedish exhibition at Underhållsmässan (the Maintenance Fair) – visit B10:42 in the Industrial Tech Startup Arena on 31 May – 3 June.

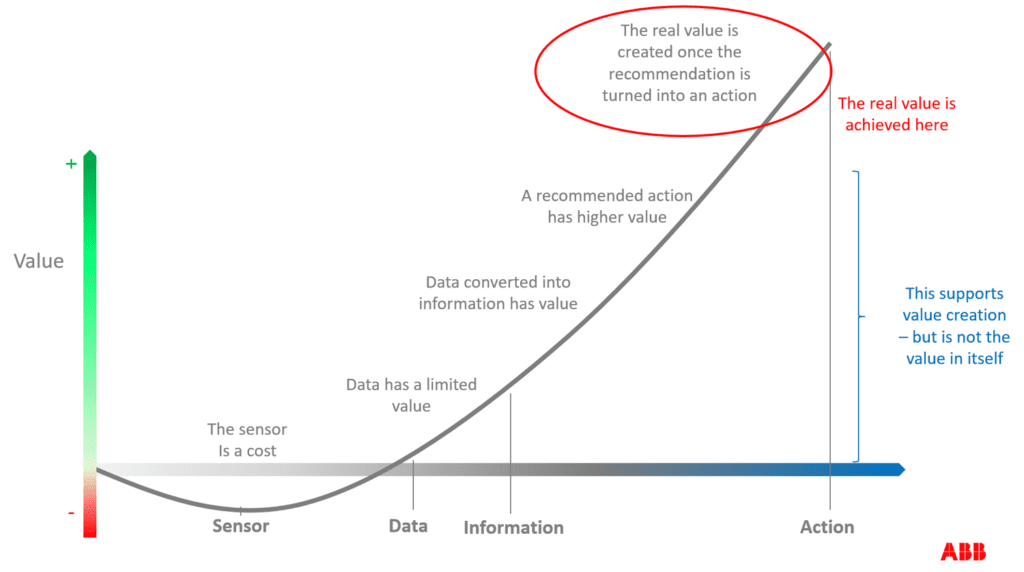

Digitalization will prove valuable once it leads to action

ABB has developed a model for digital condition monitoring which Strainlabs, as a member in ABB’s growth hub Synerleap, have taken part of. ”Digitalization in itself has no value, it is only once data provides a result that can be turned into a recommended action that it will be possible to capitalize on a digitalization investment” comments Peter Isberg.

“Let’s do a thought experiment – a factory has a maintenance engineer who inspects 40,000 bolts. An inspection takes an average of two minutes. If he inspects all the bolts and finds ten that needs to be re-tightened. The amount of value in time is only 20 minutes out of 80,000 minutes, which gives 4 minutes per thousand minutes (0.4%)!” clarifies Peter Isberg.

Industrial digitization needs to be put into perspective in several ways – including the value of reduced need to turn off the machines for maintenance and time gained that can instead be spent on value-creating work. In addition, unplanned stops due to bolts and related mechanical failure can be avoided with preload alerts which involve great potential savings for critical machinery.

(Left) Csaba Madru, CEO Strainlabs.

(Right) Peter Isberg, Digital Lead at ABB Motion.

Strainlabs is a part of Synerleap Powered by ABB.