Bolted joints have been used for centuries, yet myths and misconceptions about tightening processes still linger across industries. While torque is often used as a proxy for bolt tension, torque and preload are not the same – and the difference can be crucial for ensuring joint integrity. (Learn more: Torque vs Preload)

Leading technical training providers in Germany, such as the German Fastener Association (DSV), TÜV, and VDI Wissensforum, are now evolving their educational programs. Recognizing the need for a deeper, more accurate understanding, Markus Fischer – a certified Fastening Engineer (DSV)© employed by the SCS Concept Group, known for his extensive commitment and experience in bolting technology – bridges the gap between theory and practice, enabling engineers and technicians to move beyond old habits and truly understand the behaviour of bolted joints.

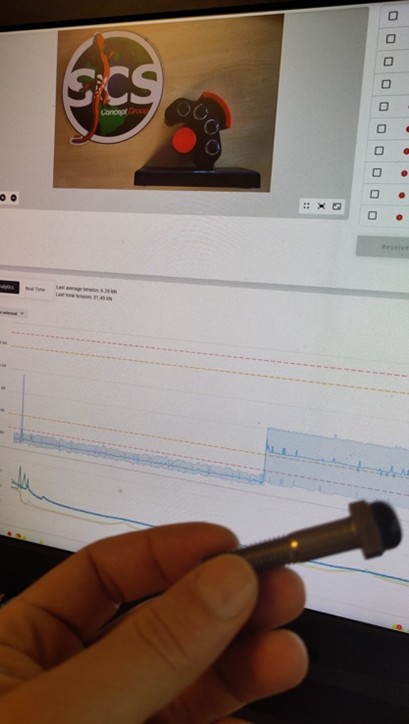

Bringing preload to life with Strainlabs demo

To complement traditional torque tools and torque-angle methods, Strainlabs’ live preload monitoring system is introduced in the training program. By adding live preload monitoring, participants gain hands-on, immediate feedback. This helps move technical education in fastening one step closer to data-driven assembly validation, preparing industries for future quality assurance challenges.

“We show that torque is not always torque. Tightened to 25 Nm, the preload values differ significantly across the joint. Seeing the numbers live makes participants rethink everything they know about assembly quality.”

— Markus Fischer, Technical Compliance Director, SCS Concept

Practical session featuring Strainlabs demo kit with four bolts in one joint, all torqued to the same value but showing different preload values, and according to Markus Fischer this is a striking, immediate way to demonstrate why torque alone is an unreliable measure of joint integrity.

Participants tighten bolts, observe real-time preload changes, and discuss the factors influencing results – such as lubrication, tool variability, and assembly methods.

In some sessions, online bolt preload data from remote test equipment are also integrated, allowing participants to observe bolt behaviour remotely and showcasing the future of digitalized fastening technology.

Results and participant feedback

The practical sessions leave a lasting impression, giving participants new tools to improve processes in their companies.

Tobias Wegner, Force & Form Closure, DRÄXLMAIER Group

(Participant in Schraubfachkraft DSV – Specialization Module II)

“The practical part in Dresden was particularly valuable. Seeing the real-world impact of user influence on torque tools, including deviations of ±20% compared to ISO standards, was eye-opening. The training clearly showed how theory translates into practice and inspired internal analyses to optimize our manufacturing processes.”

Marc Stoll, Maintenance Department, KION Group

(Participant in Schraubfachkraft DSV – Specialization Module II)

“Precision and efficiency are key for me. The training deepened my understanding of tightening technology and the factors influencing preload. The insights gained will support both my personal development and the continuous improvement of our company processes”.

Join and learn more

The content updates in these seminars underline a critical shift in the industry: moving from relying on torque assumptions to a deeper understanding of preload and joint behaviour. By participating in these programs, engineers and technicians gain both theoretical knowledge and practical, test-backed skills that enhance safety, reliability, and process optimization.

Upcoming courses:

- Schraubfachkraft DSV (fastener specialist)

- VDI Wissensforum Joint Analytics Training

- International Fastening Engineer (new educational offerings)

Further reading:

- Markus Fischer interview: The Future of Bolt Tightening

Follow the conversation on Strainlabs LinkedIn