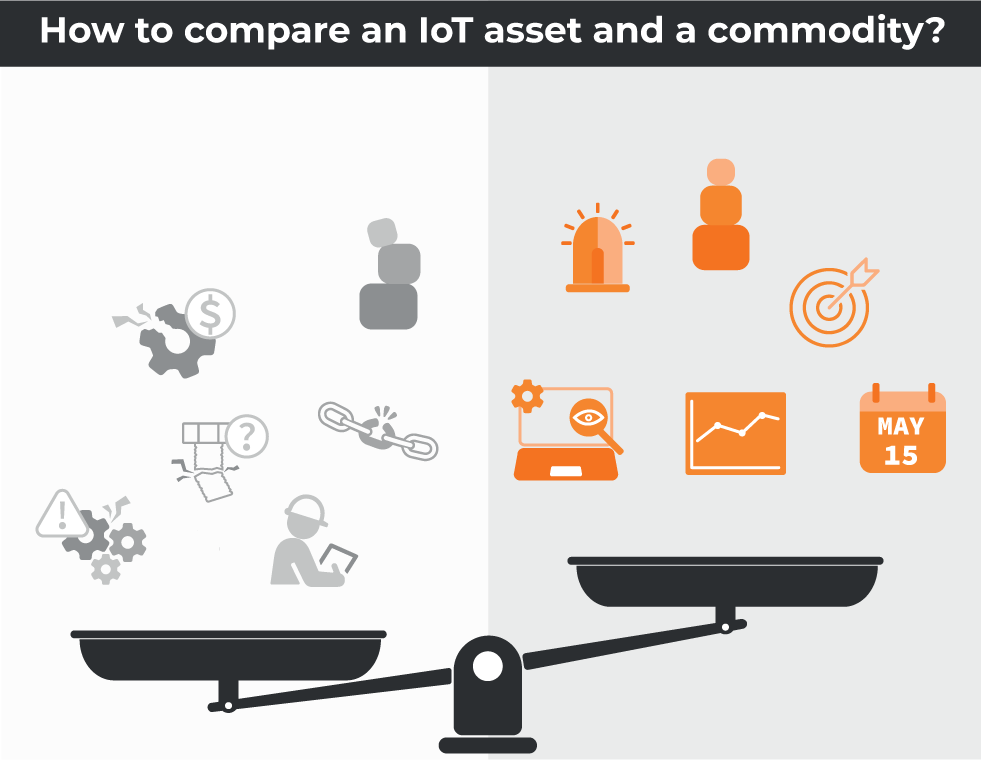

Strainlabs has developed a complete system for remote preload monitoring, alerts, and insights which turns the bolt into an IoT solution. It may seem overwhelming with digital transformation, but the key is understanding the possibilities on long-term efficiency gains, savings potential and what new types of insights can bring in product development and process improvements.

IndTech (Industrial Technology) is about digitalizing existing equipment and machinery. Utilizing the bolts mean minimum adaptation and costs to get started. Industrial applications and machine builders already see benefits from sensor data with temperature, humidity, and vibration because the next level is the mechanical insights. Getting data directly from a mechanical structure has so far been difficult to obtain but since bolts are a common way to hold structures it is also a common root cause to failure – the optimum commodity to turn into an IoT asset!

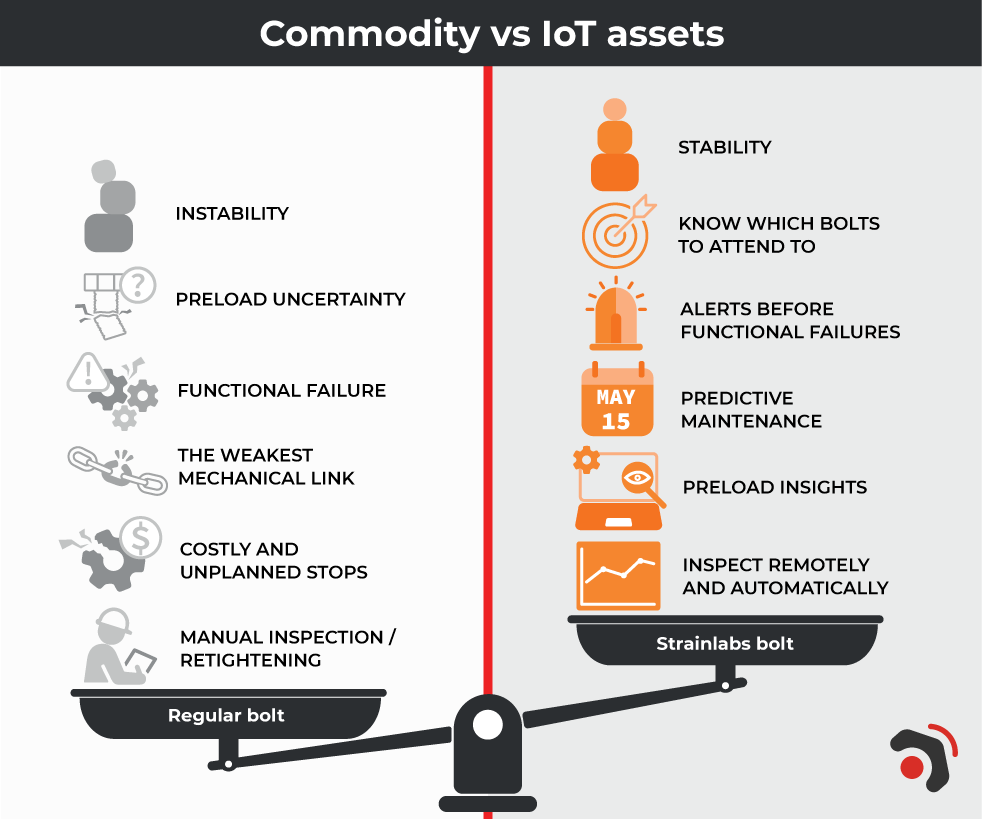

When a bolt goes from being a mechanical part into becoming an automated measuring tool it reports on the health of the mechanical structure. The main values with Strainlabs IoT bolts include:

- Avoiding failures before they happen Strainlabs System gives alerts when bolts are approaching a non-functional preload range.

- Increase uptime Unplanned stops takes on average 3-9 times longer to fix (according to Reliable Plant and various on-site studies)

- Smart maintenance Strainlabs enable predictive maintenance and reduced manual inspections which is particularly valuable in hazardous & difficult to reach areas. In addition, time spent on manual inspections can be spent on more value-creating activities.

- New insights Industrial organizations are beginning to see that digitalization is not just an efficiency race, there are multiple opportunities to get ahead of competition with the insights that mechanical data can bring.

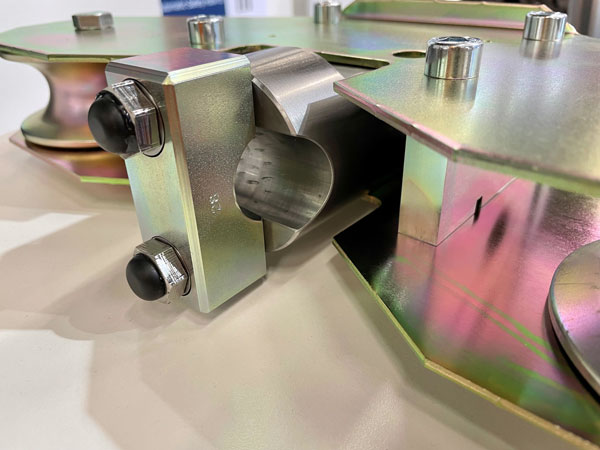

Industrial application example: Gigasense

Gigasense is an expert in crane safety and force measurement products including overload protection for industrial applications. Their solutions are used in a wide range of heavy industries including steel production and bridges. Uneven load distribution can be devastating for the entire structure and cause large costs. The company is therefore preparing to implement Strainlabs preload measurement as an add-on which will enable the possibility of offering monitoring of load distribution in wires. Gigasense has developed a prototype by starting from an existing product that already has M10 bolts in the assembly, replacing those with Strainlabs bolts will turn the bolts from mechanical commodities into an IoT asset.

Gigasense offers different solutions for measuring force in preloaded wires, this photo shows their prototype exhibited at Underhållsmässan, Gothenburg 2022. Integration of Strainlabs solution will enable remote and automated monitoring of force distribution.