Preload monitoring

Sustainability

More informed decisions

As operations become more connected, manufacturers and asset owners will be able to use data to optimize processes. A more sustainable use of machinery allows for economic development without a negative impact on ecological and social sustainability.

Automation, remote maintenance and inspections unlock possibilities to reduce travel, transportation and ensure safe and effective maintenance.

Internet of bolts

Strainlabs is leading the industrial digitalization of bolted joint technology - challenging time consuming and inefficient use of resources.

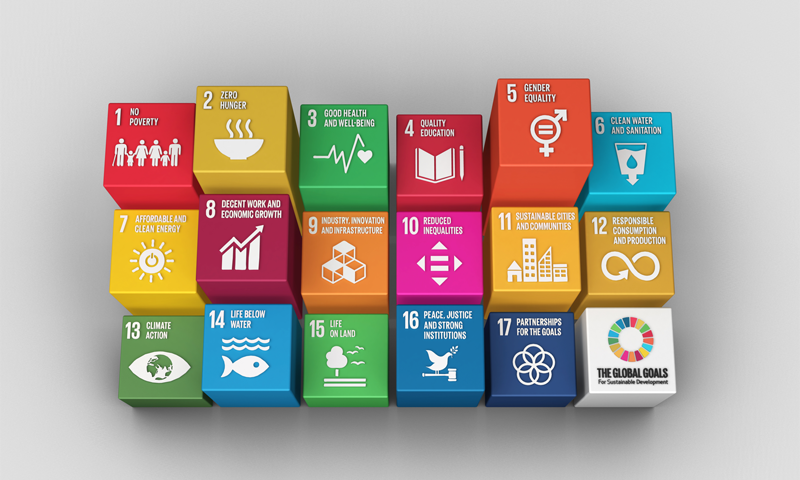

Sustainability & Agenda 2030

Preload monitoring of bolted joints supports asset owners and maintenance teams to take more informed decisions – contributing to workplace safety, employee training and overall increase in sustainable operations.

Preload monitoring of bolted joints supports asset owners and maintenance teams to take more informed decisions, employee training and overall increase in sustainable operations.

Preload monitoring by Strainlabs is in the absolute front line of IoT sensor technology for bolted joints, enabling continuous improvements across multiple applications and industries.

Preload Monitoring with Strainlabs System contributes to sustainable production patterns. This includes for example reduction in transportation of spare parts, travel of personnel and produced goods which support climate action.

Subsequently Agenda 2030 goal 8 (descent work and economic growth), goal 9 (Industry, Innovation & Infrastructure) and goal 12 (Responsible Consumption & Production) are Strainlabs focus, and our aim is to through innovation and technical development offer means for:

- Improving operations and contribute to Industry 4.0

- Contributing to the society and environment by influence and create new possibilities for businesses.

- Make decisions and priorities more resource efficient for asset owners.

- Promote safe working environment.