Even though Strainlabs is mostly known for IoT bolts – it is the holistic end to end system with the communication from bolts to router to presenting preload data in an over viewable system that makes Strainlabs System valuable. Strainlabs Analytics is a robust and powerful software designed to visualize the status of your bolted joints, enable remote surveillance of multiple joints, machines and even sites.

Digital twin of the health of your key mechanical structures

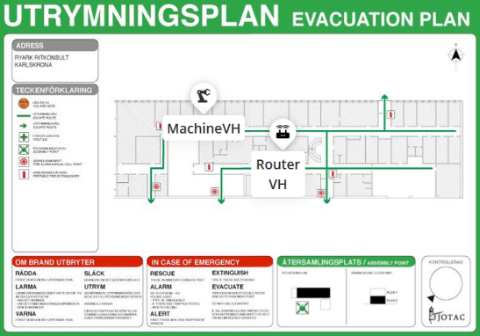

Today in IoT, Digital Twin is a popular concept where you create a replica as close to reality online. With Analytics we use pictures, blueprints, floor plans and coordinates to bridge the computer world to the industrial reality. Let’s take a quick dive into how a Digital Twin can be created and how you can benefit from storing logs about ‘Five Ws’ (Who, What, When, Where, Why) regarding Digital Twins on your Site.

Analytics uses a tree structure to create the foundation for how your ‘End User Organisation’ will take form the following levels in a tree structure:

├── Sites├── Machines├── Joints├── Bolts

Sites: create several sites within your organisation, size and location does not matter. Give Users different access rights depending on responsibilities. Drop a pin on a map or use a floor plan over the facility, this is used later on to place your machines and routers on. In the Notification panel you get a quick overview of your Sites status.

Machines: Placed within the sites, place on a map with coordinates or pin them on the Site image and add an image like a blueprint or overview of the machine. Create several machines. Ability to put machine into ‘Maintenance Mode’ for pausing notifications and noting down information about condition during maintenance.

Joints: Preferably created by adding a close up image and pinpoint where it resides on the Machine image/blueprint from above.When tightening, the whole joint can be placed in ‘Real Time’ which allows to you follow preload status on joint level continuously during tightening.

Bolts: Pinpoint related to the joint or individually. Assign a descriptive name when helpful to differentiate or describe installation data (adhesive Y/N) in addition to the unique Bolt ID. Bolts store historical data, for the unique position or if it has been move from a previous joint.

Values with analytics in operations

Manual inspections during operations involves both risks and cost which can be reduced by remote monitoring as bolts are only retightened or visited when and as needed. Strainlabs is a turnkey IoT system where key parameters include increasing control (traceability), reducing risks (notification) and providing learnings (storing of logs). This is vastly different and allows the ability to minimize that the entire production chain is affected when a bolt is about to loosen.

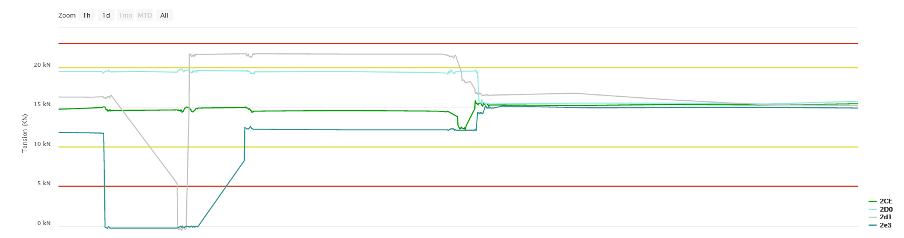

- Tracability Each bolt has a unique ID and keeps a history of all the changes and events that is associated with that ID. The bolt in the graph below was changed to a joint called “Rig Joint” and then changed back to “Strainlabs Demokit A”. This makes it easy to look at what has happened during the lifetime of every bolt.

- Notifications is a system where messages from your bolts are being displayed and can thus be acted upon proactively to ensure uptime. The whole idea of Analytics Notifications is, quite the contrary, not to look for notifications but instead to get a quick glance at Sites or Machines that no Notifications are active and they are operational. This way maintenance can be implemented in daily operations on several Sites scattered over the globe with ease.

- The Logs stored in Analytics create valuable data for reflection and improvement. Most companies have a structural maintenance program but what happens in between those intervals are often in the blanks. Analytics is built to surveillance Sites 24/7 and if something is detected, a Notification is shown on the Web Site and the Machine or Joint can be set in Maintenance. While doing that a form is required to be filled in to proceed where you must select the severity of the maintenance which is Critical, Warning or Information among with other necessary information. All to keep track of the events happening on a Site.

Further Strainlabs real time mode is a game changer for installing bolted joints correctly from starts as there are many challenges involved in ensuring a correct bolt installation. The ability to follow up that the preload achieved in the bolt from the start was correct is very valuable to ensure safe and efficient operations.