Strainlabs IoT bolting company and global railroad equipment company Vossloh has entered a strategic partnership to drive digitalization and sustainability in railway maintenance. Vossloh connect brings together innovative solutions to customers on an integrative platform. Vossloh customers will be able to monitor Strainlabs Bolts and Strainlabs has been added to the portfolio of the international sales force.

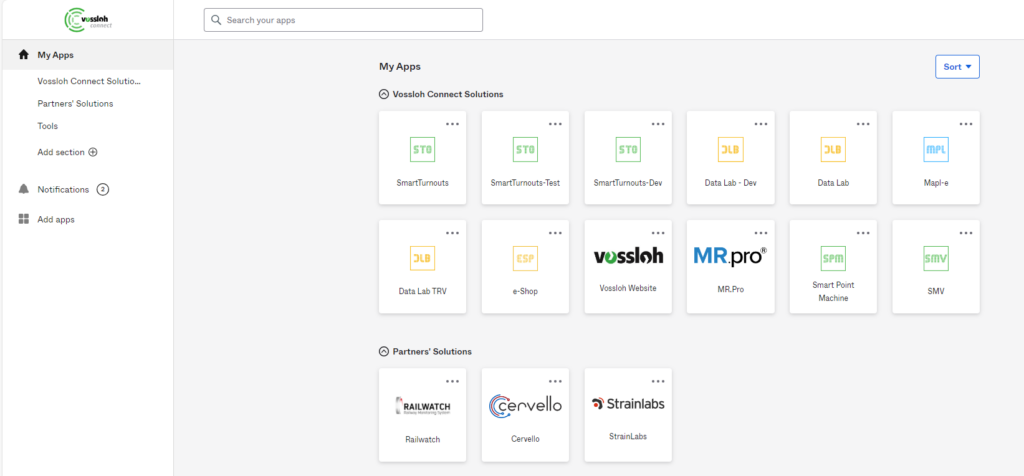

Vossloh Connect is a digital platform offering a set of rail infrastructure solutions tailored for specific customer targets – Strainlabs is available through the user-friendly platform.

Strainlabs is one of the first partner technologies launched on Vossloh connect. ”Strainlabs brings an innovation in connected bolt technology to the platform” says Pierre-Henri Bougeant, Head of Digitalization at Vossloh. “With Strainlabs one can monitor the integrity of rail infrastructure with unparalleled precision, gathering real-time data on the stress and strain experienced by crucial components. This enables proactive maintenance and enhances the overall reliability of the rail system”.

Predictive maintenance with Strainlabs & Vossloh connect

Bolt security is a vital part of public safety. Structures are often exposed to extreme conditions and temperatures including dynamic loads and vibration. It is time consuming and inefficient with reactive and time-based maintenance. Strainlabs can support industrial digitalization including the enablement of real time data, predictive and condition-based maintenance. Key benefits with adding Strainlabs to your maintenance routine through Vossloh connect include:

- Simplified digitalization journey – same interface with Strainlabs integrated in Vossloh connect. For multiple digitalization initiatives one common user interface and login simplifies when implementing several new innovations.

- Faster ROI – setup combining extensive railway maintenance experience with innovative predictive maintenance solution.

- Cost efficient – simple and efficient way to get started for actors in the railway industry.

“Most industries experience challenges in aspects of technology, operations and business models when trying to implement third-party digitalization. Further, the industrial IoT-landscape is still somewhat fragmented. Vossloh has created a genius platform which simplifies for railway costumers to navigate and progress their digitalization”. comments Csaba Madru, CEO and co-founder of Strainlabs. “Through this partnership we have the potential to together with Vossloh drive a legacy industry forward with efficient and sustainable maintenance methods”.