Strainlabs systems

A complete IoT System

Unique & patented solution

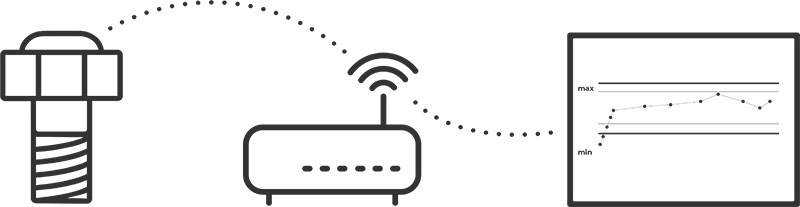

Strainlabs sophisticated solution includes bolts with patented LED sensors that communicate via a router to Strainlabs Analytics.

- Strainlabs Bolts Connect an unlimited amount of preload sensing IoT bolts using patented LED-sensor technology to measure preload.

- Strainlabs Routers Pre-configured routers to receive and upload data results from Strainlabs Bolts to Strainlabs Analytics.

- Strainlabs Analytics Enables remote monitoring and alerts for Strainlabs Bolts. Aggregates quantifiable and actionable data.

A Complete monitoring system

Strainlabs System enables monitoring of multiple applications, machines, or sites by developing the industrial digitalization of bolted joint technology.

Traditional maintenance meets remote, automated and wireless condition monitoring

Bolted joints are a key source for inspections as well as reoccurring retightening and maintenance needs. With Strainlabs, some of these costly processes can be digitalized and easily integrated into a modern maintenance strategy. This will allow for more efficient time spent by maintenance teams whilst enabling a tighter inspection scheme and faster identification of bolts approaching a non-functional preload range.

The system includes custom alerts and user-friendly dashboards to support monitoring and insights per specific bolt or joint and even machines and entire sites. For OEMs and service providers, Strainlabs Preload Monitoring can be offered as part as a service offering to enable maximized asset output & productivity for asset users.

Internet of Bolts

When and where is it relevant to implement Strainlabs System?

Due to the wide use of bolted joints across industries, Strainlabs can provide valuable & actionable data to virtually any business, process or asset.