What is a tensile strength test and why is it performed?

A tensile test is a common test for verifying the axial strength in bolts. It is a clever process since with one test you check three vital parameters at once – the tensile strength, the yield strength and the bolt elongation. What values a specific bolt type should meet is all covered in it’s ISO standard. “At Bumax we ensure that stainless steel bolts always follow ISO 3506-1 and as part of our standard quality assurance process we always test minimum two bolts of each batch in this way” explains Anders Söderman.

The test is made by assembling the individual bolt in the tensile testing machine, a force is gradually added and eventually the bolt will break. For tensile and yield strength the machine provides the value directly. “As an example, an A4-80 bolts is required have a minimum of 800 MPa in tensile strength and a minimum of 600 MPa in yield strength. Before and after the test the entire length of the bolt is measured to determine the elongation. The standard ISO 3506-1 specifies that the elongation after fracture for an A4-80 bolt should be minimum 3 times the diameter for of the bolt divided by 10 which means that an M30 should elongate 9 mm or more to follow the standard (0.3 x d = 0.3 x 30 = 9 mm)” Anders exemplifies.

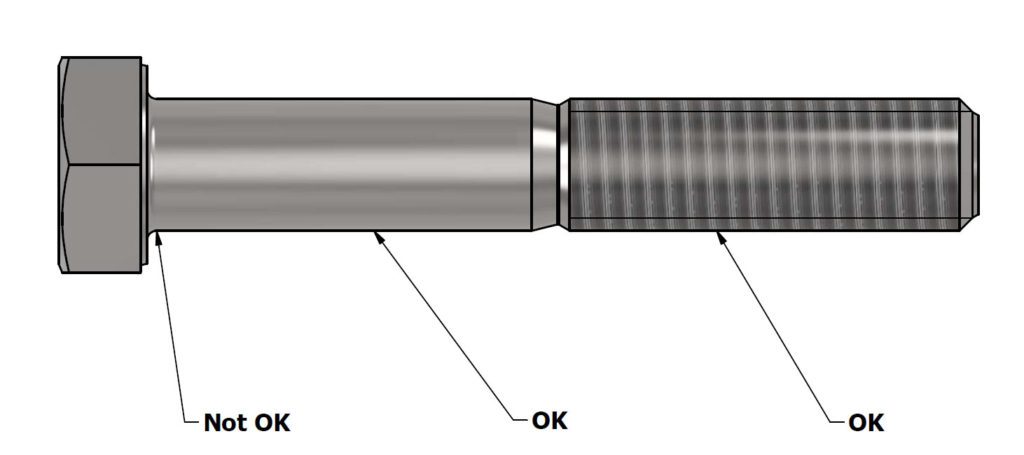

Fracture must occur in the shank or in the threads

In a tensile test, the fracture is not accepted neither in the head nor directly in the transition between the head and shank. The fracture must occur in the shank or in the threaded part (see illustration).

For Strainlabs Bolts, with the hole for the sensor in the head and towards the shank, it is beneficial to use partially threaded bolts of the standard ISO 4014, since the load supporting cross section in the shank is larger than in the threads.

What was the result when you tested Strainlabs’ Bolt?

“We tested the entire standard range of Strainlabs Bolts made with BUMAX 88 bolts in sizes M20, M16, M12 and M10 in our laboratory in Åshammar, Sweden and all bolt passed the standard” concludes Anders and continues: “For M16 and M20 we couldn’t detect any difference in strength and performance. For the smaller sizes M12 and M10 the strength is well above the required strengths in the standard as well, but the test illustrates up to 13% of strength loss due to the drilled hole for Strainlabs sensor. However, if an application is using standard A4-80 bolts and then switches to Strainlabs Bolts made with BUMAX 88 or BUMAX 109 the result is still a stronger bolt with higher tensile strength than the standard A4 bolt, so I don’t see that the drilled Strainlabs design is a problem in terms of bolt strength”. Bumax bolts and material normally fulfil both the stainless tensile requirements and the higher strength requirement specified in corresponding carbon steel standard so there is room for that minor loss that the hole cause on smaller bolt sizes.

The tested Strainlabs Bolts were made using Bumax 88 bolts and for a customer using this bolt type we could easily propose even stronger material i.e. Bumax 109 (10-20% stronger) or Bumax DX129 (Duplex stainless steel). “We are used to finding solutions that is well beyond the standard requirements. With these tensile strength results on Strainlabs Bolts we can encourage our customers to test this remote solution for automated preload monitoring and preload insights” concludes Anders.