The golden rule of mechanics basically claims that “What you win in force you will lose in distance”. However, as we pioneer the digitalization of bolted joints we have to balance the possibilities of the technologies we use – and the functionalities IoT bolt users find the most valuable.

Digitalizing safety and enabling predictive maintenance

We know that bolt preload needs to stay within the safe preload range for bolts to operate correctly. Historically various practices have been common including measuring torque input, torque check inspection and retightening inspection. Besides resulting in a lot of manual work, these methods don’t bring a lot of accuracy nor insights on the actual preload and how it changes over time.

Finding the sweet spot with IoT bolts and performance

The fact that industrial technology or IndTech now presents new methodologies to measure bolt preload automatically and remotely is revolutionary in itself. However, it also means that the best practices and what is possible to expect from a modern bolt changes and new important values emerge – however the expectations for this kind of technology are not yet defined. How to balance the requirement specification of an embedded end-to-end IoT system and tie it into a predictive maintenance strategy? We see a fast-growing interest in understanding what is possible and the technical boundary conditions of new innovations leading the way.

Launch of article series on performance

Strainlabs is kicking off a 2023 article series that will cover all the key aspects of performance in our technology-leading IoT System. We help you understand the entire scope for defining the required technical performance within the modern, smart, connected, and digital bolting arena.

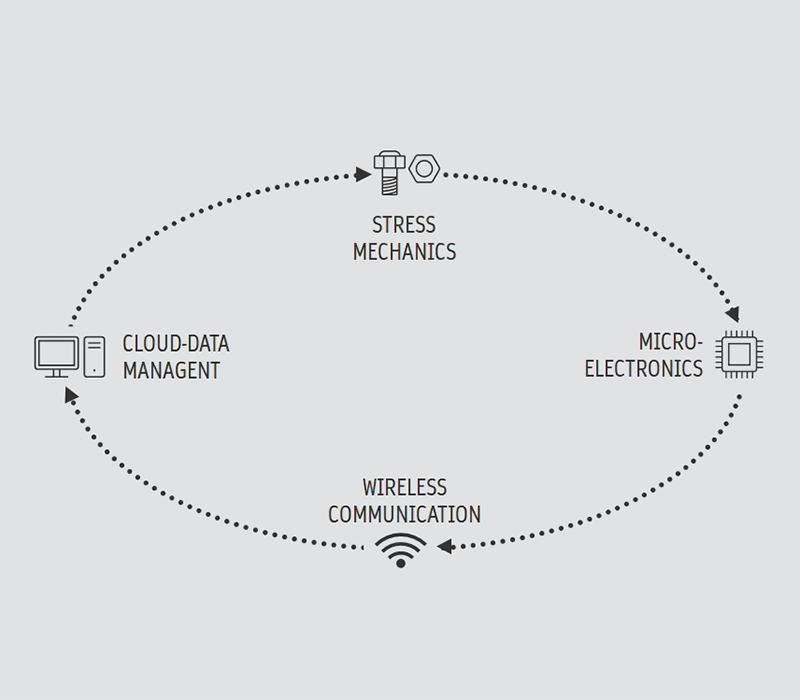

Strainlabs IoT innovation and technology range is unusually multi-disciplinary and designed to suit best-in-class predictive maintenance strategies.

The first article will be published shortly – follow us on LinkedIn or sign up for our newsletter below in the footer so that you don’t miss out on any of the articles and IoT bolting insights.