Daniel Reimhult is a consultant complementing Strainlabs internal development team’s expertise when it comes to perfecting the measurement system in Strainlabs IoT bolts. He brings his long experience with embedded systems.

Question: What types of industrial problems can embedded systems solve?

The fact that we have a range of small computers in literally any production unit today says a lot, embedded systems are interacting everywhere to solve specific tasks across our society. As technological development advances new possibilities arise. An example of an extreme case is vehicles embedding extremely powerful computers to process enough information to enable self-driving of the vehicle. If we take Strainlabs, the target is to help industries implement predictive maintenance. Then the technical challenge is more about designing something from scratch and getting the desired functionality and performance into the size of a fairly small bolt and designing the system around it. I would say that Strainlabs embedded IoT solution is well in sync here as a lot of what the system does wouldn’t have been possible going back some 10 or even 5 years.

Question: What would you say are important when it comes to developing an embedded system?

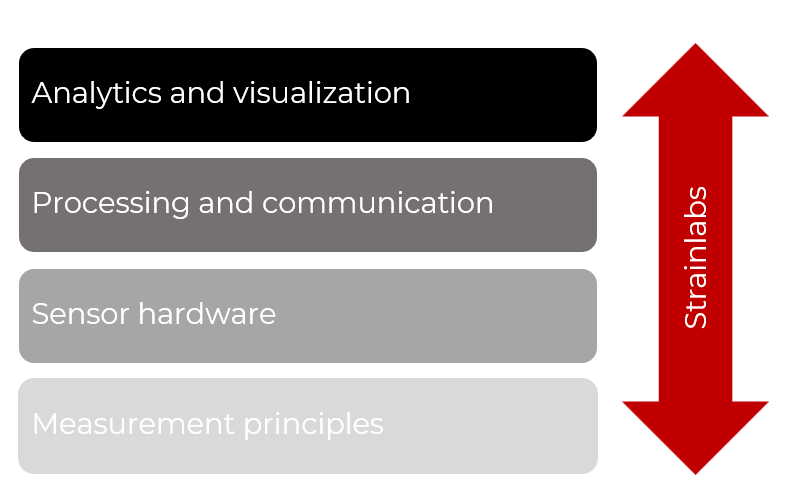

I’d say it is a multi-layered product development process. The foundation of embedded systems is the principles involved in making correct measurements. They in turn rely on the hardware to successfully execute the job. To bring full value from the measurements, the data needs to be processed in a smart way before communicating and visualizing the results. For me it is a question of maturity as these things are not sequentially developed in one part and then the next – everything needs to be developed in parallel. Having end-to-end control and maturity throughout the technology stack is key to going to market as Strainlabs has done. I’m happy to have contributed some parts in some of the layers on that journey.

Figure 1: Strainlabs end-to-end system encompasses a large scope in terms of technologies involved to successfully measure and present preload data in an automated process. The customer value is refined upwards in a chain of interdependencies in the embedded system.

Question: What dimensions are involved when a new embedded system is developed and launched?

I would say that there are three key dimensions that interlock – the development, the product functionality, and the market itself that must be balanced.

- R&D and productification

Everything from discovering and defining the measuring principle, to designing the hardware and software. Then the experiments and prototyping that comes with it as it must be defined how everything interacts. Productification is how to go from prototype to volume production and to meet certifications. With a patented measuring technology, the team, the tooling and needed partners – I’d say Strainlabs is in a good place for their scale up journey meaning the focus is shifted from productification to the actual scaling activities.

- Product functionality

Measuring systems rely on a chain of interdependencies to be successful and work from end-to-end (see Figure 1). Strainlabs has the ownership, control and understanding of their end-to-end system and is, therefore, capable to customize and develop every aspect of the product. Something I see as particularly important in a niche industry i.e. to be able to improve user experience in managing bolted connections and bringing value to that process. The maturity sign here is the ability to seriously begin a focus on broadening the range.

- Market

Without bringing market value the R&D and the technology of the product is not worth much so everything is interlocked in that sense. Strainlabs customers are always seeking to optimize their operations and processes, and it is a relatively simple task to estimate the value of Strainlabs products in this context. This may not be as simple in other industries, where explicit savings are not so apparent and other means of defining the customer value is needed, such as legislation compliance. In the case of Strainlabs, the customers know the cost of downtime and log their maintenance routines and they can calculate the value the Strainlabs IoT Bolt system brings. I find this motivating for the team and for everyone supporting the journey.

Question: How to manage key success factors and dimensions over time?

I would say that prioritization and continuity are key, especially when there are a few people involved and a broad technical scope. I think there needs to be a substantial parallel activity on the fundamental domain knowledge to be successful in building a scalable solution that is durable long-term in the marketplace. Working with Strainlabs and their IoT bolting system I find that the team has an impressive capability of keeping their eyes on the horizon while advancing the go-to-market product. Not all companies are clever enough to dedicate time and energy in a parallel way.