Strainlabs System ensures structural integrity with precision, enabling optimization of resource allocation and maintenance planning. Bolts in transporation nodes are a vital part of public safety. Placed in remote locations, structures are often exposed to extreme conditions and temperatures. Automated remote inspections and reporting enable cost saving, reduced delays and downtime.

Strainlabs’ engagement in infrastructure is not just about solving today’s challenges but also about shaping the future. By combining e-bolts or smart bolting technology, Strainlabs is enabling industries to move beyond reactive maintenance toward a proactive, data-driven appor smart boltingnerships and case studies spanning railways, bridges, and amusement parks, the company is at the forefront of a smarter, more sustainable infrastructure digitalization.

Gösta Rydin, Sales Manager:

“The cost implications of infrastructure failures are enormous, we at Strainlabs see that over and over again. By invest in digitalization and automation, we’re closing the gap in maintenance deficit, while ensuring availability of critical assets.”

Why a focus on construction and infrastructure?

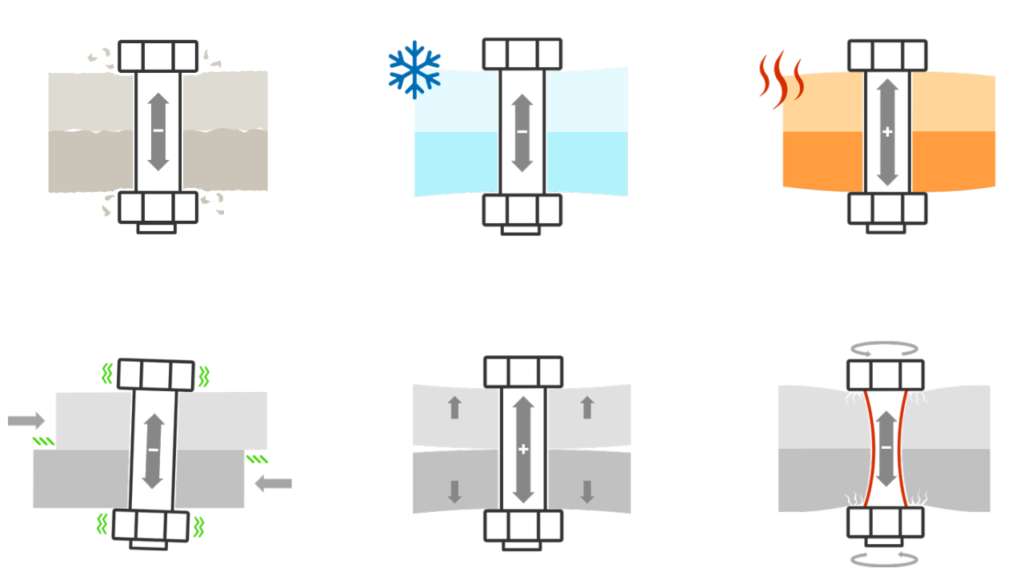

Preload is fundamental in maintaining the stability of bolted joints, which are critical across infrastructure sectors such as railways, bridges, and amusement parks. With the remote locations and critical nature of these structures, they are highly relevant applications for Strainlabs’ remote preload monitoring technology.

Combined with AI-driven models and algorithms, these data points enhance system understanding over time, allowing for even more accurate predictions of asset behavior and failure risks, ultimately optimizing Predictive Maintenance and Operational Reliability.

Infrastructure partnerships & applications

Breif overview of activities and more information:

Vossloh: A Partnership Transforming Railways

Strainlabs’ partnership with Vossloh and participation in Vossloh connect is a great example of two companies with a potential to together change an industry. See video from Strainlabs live demo of Track fastening system installation. [Read more].

The Öresund Bridge: A Beacon of Smart Infrastructure

In a pioneering case installation, Strainlabs has brought its technology to the iconic Öresund Bridge, one of Europe’s most significant infrastructure projects. This collaboration highlights the scalability of Strainlabs’ solutions and their potential to address diverse challenges in large-scale infrastructure projects. [Read more]

Gröna Lund: Safety in Amusement Parks

Infrastructure innovation extends beyond railways. At Gröna Lund, Strainlabs’ sensorized bolts are ensuring the safety of high-stress structures like roller coasters. The ability to monitor preload and detect potential issues in real time offers an unparalleled level of assurance in such dynamic environments. [Read more]

Swedish airport: Airport runway lights

Strainlabs’ sensorized bolts are enhancing safety and reliability in airport infrastructure. By enabling real-time preload monitoring and predictive maintenance on airport light, Strainlabs enable automated inspection routines and increased safety. [Read more]

Baptiste Simon, Transport & Infrastructure GAM:

“Track availability is the cornerstone of rail infrastructure, making our partnership with Vossloh highly strategic. Strainlabs’ technology enables operators to proactively address issues, reducing downtime and maximizing efficiency. Beyond rail, my role within Strainlabs underscores the critical impact we have in enhancing reliability across Infrastructure and Transport.”

As we continue to expand our impact, our unwavering commitment remains the same: delivering data-driven solutions that enhance the resilience of critical infrastructure worldwide—whether for fixed installations or mobile assets, in both emerging and equally demanding operational environments.