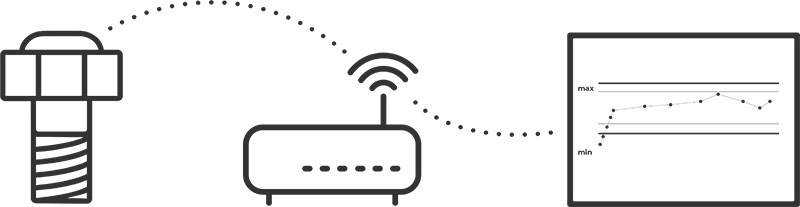

Strainlabs Analytics is a modern way to reduce manual torque checks and inspection costs whilst increasing safety through user friendly graphics and preload alerts.

Preload monitoring can easily be integrated into maintenance and inspection schemes as a regular task to remotely overview specific machines or several sites. Strainlabs software enables actionable data from day one, including for example review of achieved preload after installation as well as monitoring preload distribution in a joint with multiple bolts. The system offers custom alerts for bolts approaching and exceeding its functional preload range. Strainlabs Bolts will further report on important data for remote management including battery level, antenna reception and temperature data.

Unique offering for end users as well as OEMs and Service Providers

Strainlabs Analytics is available as a platform for end users to be reviewed by existing maintenance staff for digital inspections and maintenance decisions. In a recent update, the software has been released with features to further support through digitalization services by OEMs and service providers. Digitalization of existing industrial assets, IndTech (Industrial Technology), is often made in partnership with digitalization and Industry 4.0 / Smart Manufacturing consultants. Due to bolted joints being the most common industrial mechanical component, “Preload Monitoring as a Service” can become a quite valuable data source as it enables for example predicative maintenance.

With Preload Monitoring asset owners and service providers can stop a process before a functional failure and complement time consuming maintenance routines with digital inspections. Testing Strainlabs System is simple and a cost-efficient turn-key solution to efficiently initiate a digitalization journey for machineries and assets.