We interviewed Markus Fischer – a Fastening Engineer (DSV)© employed by the SCS Concept Group and with extensive commitment and experience in the field of bolting technology, joint analysis and process optimization – who is active in the field of bolted joints and tightening technology in numerous standardization organizations and technical committees such as VDI (Verein Deutscher Ingenieure), CEN and ISO. Markus Fischer is straightforward and brutal in his assessment of the state of digitalisation “in torque” and how some industrial beliefs and practices need to be updated.

Where does your deep fasciation of bolt tightening come from?

Bolts are not only ubiquitous, but they are also ambiguous and complex safety systems. The German automotive industry alone assembles an estimated 2-3 hundred million fasteners per day. It stands for best in class in tightening tech and still can be found, although much less frequently than others, on recall lists from NHTSA in the US or RAPEX in Europe, just to name two. Even coffee machines have safety critical assemblies with recalls due to screw failure. Or take another segment, the wind industry. In early 2024, a wind farm in Germany had to be shut down because a 15-tonne rotor blade came off a wind turbine. There is still so much potential to be realized with the bolt – I don’t think there is any doubt about that.

I started out almost 20 years ago selling low torque / micro screw assembly solutions and realized that I needed to understand the customer’s processes to change things for the better. I started analysing what could be optimized, the design, the assembly, the quality assurance, what standards to follow and why and so on. Deepening and broadening my knowledge and expertise is an important and ongoing goal for me. This obsession led me to set up a tightening technology academy with my first employer in the industry, where I also began to work within the training programme of the German Fastener Association (DSV). At the same time, I became heavily involved in organisations such as the VDI (Verein Deutscher Ingenieure), which is responsible for many internationally recognised standards for measuring and testing in the assembly sector, as well as the VDI 2230 series on bolted joint calculation. Later, VDI also sent me to CEN, ISO and VDA, so I became the liaison engineer for several standards. There is actually a lot going on right now about whether we are measuring torque and angle correctly – or whether we should be measuring those things at all. Another question is how we can use artificial intelligence and so on to detect or even prevent difficulties in the tightening process.

How can digitalization improve bolted joint assembly?

To be honest, even though I work with torque and angle – we as an entire industry are basically measuring the wrong thing. And when we measure torque and/or angle, we usually do so with a dangerous credulity that urgently needs to be replaced by professionalism and facts. As a matter of fact, threaded fasteners can have several functions – “having the right torque” was never one of them. Let me give you three examples from the current standardization work about the struggles of torque and angle measurement before we talk in more detail about what is really needed:

1) Torque calibration can only be performed statically. Ask your national authority, e.g. the Federal Physical-Technical Institute, and they will confirm this to you. But all we have done in the last decade is to go faster and faster in screw assembly, sometimes several thousand rpm – defying the laws of physics. With the revised VDI/VDE 2645-2 on machine capability and the new VDI/VDE 2645-1 on measurement capability, the VDI will publish the results of clutch tool maximum speed tests in order to maintain the three main goals of repeatability, comparability and traceability in tool testing. And the results are in the range of 300-400 rpm rather than in the thousands. And this, of course, ignores all the other important speed-sensitive effects of assembly such as friction, joint relaxation, etc. If you want to use a high speed tool, you have to have a very high level of expertise to make it work, that’s for sure. Oh yeah, and angle measurement becomes even more difficult when you’re moving fast or even discontinuously – and let’s not forget that angle measurement is in most cases triggered by a dynamic torque measurement… ahhh it’s not nice to dig too deep and only trust e.g. brave marketing brochures with lots of buzzwords.

2) Another example, in ISO we are currently revising ISO/TS17104 (equivalent to VDI/VDE 2649) for pulse or impulse tools – softer but also more precise rotary tools than impact wrenches, but with their ergonomic advantages. The performance test described in the standard is very advanced for its time because it relies on clamping force rather than torque to test the capability of such tools for several reasons. Great, problem solved – we just need to change this procedure for all of our torque tools. But wait a minute. Unfortunately, the existing standard has not been widely adopted by either tool manufacturers or users. And the current working group is struggling to prove reliable comparability between different test systems. What will frustrate pulse tool users even more is the fact that angle measurement is not even considered in this or any other pulse tool standard, yet the functionality has been sold with the tools for almost a decade. Recognizing the frustration of users, the VDI started another working group last year to finally find a pragmatic way out of this dilemma. But be aware that any result from this working group will require a high level of qualification and know-how on the part of the users.

3) A similar problem exists with high-torque tools that are driven continuously or intermittently. For about seven years, the VDI tried and failed to develop a specification for such measuring equipment. Now the DKD (Deutscher Kalibrierdienst) has taken over and is trying to reach a consensus with the manufacturers so that users can get repeatable, comparable and traceable results when testing their tools.

Yes, of course, you could say that all of the above worked somehow in the past, but you have to admit that this is a less than satisfactory status for many users. And in the case of liability issues, it was and is an even bigger problem. The problem is, we had no other means in the early days, so the entire industry was built around torque measurement. It is time to appreciate the complexity and find ways to get better insights to make bolted assembly more economical and also reduce failures. Of course, you immediately think of AI, who wouldn’t? And the industries really hoped to take the data, standardize it, add AI or machine learning, and solve all the issues in one instance. And they were doing that long before AI was popular and mainstream, but so far it hasn’t worked. Even the new car manufacturers, you could say digital natives in the automotive industry, have not been able to cut the Gordian knot. I really believe we need digital tools, that’s not the point, and every step forward is a good step, but right now we don’t see the big leaps in the tightening industry.

Is digitalization finally slashing the myth of torque as sufficient information?

Yes, or at least I hope so. Right now, a lot of people are trying to dig deeper as more and more data analytics people move into our hemisphere. Data analytics people are not as crazy as we tightening people, who believe in torque. They look at the broader challenge and what are relevant and maybe sometimes even not so obvious attributes in the assembly or for the quality of a joint. What data can you get beyond torque and angle? We’re in a rethinking phase to figure out what’s really going on, and that’s the great thing about algorithms and AI. Humans can look at up to about three aspects and analyse them. But if you have tool data supplemented with insights on material, temperature, friction, locking mechanisms like adhesive, then maybe we can learn the expected clamp force for the lifetime. Toque never did it alone, you always needed at least an angle and sophisticated measurement to add any value.

Today, the only way we can test the results of bolt tightening is after the fact, i.e., by loosening or retightening. Then, if we have not done a proper pre-analysis of the joint, we again have no information about the clamping force and are more or less back to zero. And it’s even old news, as you can read in VDI 2230 part 1 chapter 5.4.3.2. It is really frustrating sometimes, but also motivating for me, that measuring is not as easy as many in tensioning technology thought. So kudos to Strainlabs for pushing and thinking differently about how to measure these critical issues and provide new attributes. Preload is much closer and more relevant to know compared to torque. We also now see that more and more industries are starting to realize that torque is an issue – and that they need more information to safely assemble bolts.

What are the industries doing to improve bolt tightening?

Of course, the different industries have recognized that they have significant challenges with torque. There is a new working group in the VDA (German Automotive Industry Association) to find the relevant attribute for safety critical joints. The goal is to bring together experts from different knowledge silos (bolt manufacturers, coating experts, joint designers, assembly experts, etc.) and build a universal matrix of attributes and effects that any data scientist can use later to run their algorithms.

There’s also the question of communication between tools, measurement systems and, let’s say, master systems. What is the right language or protocol to use? Is it MQTT, OPCUA or the already widely used XML? Or will another code finally bring all the data together and bring Industry 4.0 to life for screw assembly?

There is also a new European standard in the railway industry, EN 17976, which specifies, to check for example for bolt elongation if the bolt is critical. They also use something from the European Standard for Steel structures EN1090-2, which tests for shear forces as an effect on the bolt and clamp force, which can be significant, as well as temperature information and relaxation. Sometimes it is necessary to test the entire joint structure with a field of bolts to find out if it can withstand the relevant working loads throughout its lifetime, not just during assembly.

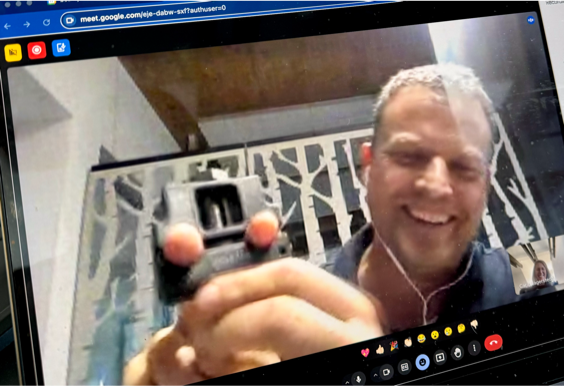

Markus Fischer with his demo gadget to illustrate how a bolt acts like a spring in an assembly including the differences between torque, pre-load and clamp-force.

What recommendation do you have for maintenance managers?

My key takeaway is that people are overwhelmed with complexity from many sides in their professional lives, but they still need to use their own heads and not blindly trust the big players. With “bolt assembly”, the thinking is that anyone can do it – it is easy and nobody needs to learn it. But this is wrong. In comparison, welders need 3 months of full-time training to get a certificate and a license to work. For trheaded fasteners – nothing. There is a lot of knowledge about bolting and it is not black and white. The company I work for, SCS Concept, is very much about supporting with knowledge, learning together and enabling companies to use their existing tools in the most effective way. In my experience, creativity comes from outside the large corporation, which is why a group of engineers started SCS, a relatively young company at only 20 years old. But our team of nearly 200 tightening enthusiasts around the world has already earned the trust of many small and large companies alike. We empower you to enjoy your #Freedom – I like to say.

Cheap assembly is available everywhere, but quality assembly requires ingenuity, skill, and the right people to challenge the status quo. Torque does not give you knowledge. If you assemble bolts to torque, if you have no idea of preload or clamp force – you are basically “screwed”. Companies like Strainlabs are important and are a way for customers to have measurements that are more related to their goal – to ultimately know clamp load. This commitment to improving measurement techniques is an asset to the industry. To make a difference, the people responsible for bolted joint safety need to get out of their comfort zones and work in new ways – it is also more rewarding and fun this was!