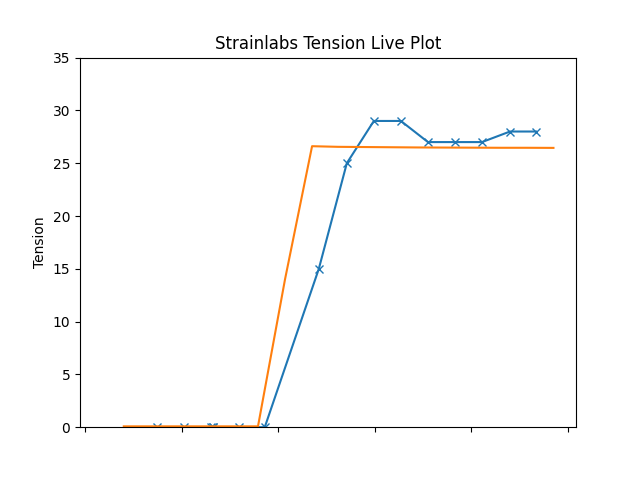

To answer this question, we first must understand the basics of a bolt that has been tightened. A bolt may seem rigid but when exposed to a force along the bolt’s axis it is elongated elastically until the yield limit of the bolt material is reached. The relationship between force and elongation is linear. So, when does light enter the room? Light is mostly used to light up our environment and enable us to see dark places. However, light is used as a basis for a variety of scientific measurements methods. In Strainlabs Bolts the light intensity is based on a cavity in the bolt. A small hole is precision drilled in the bolt along its axis to create a cavity. When the bolt is tightened the cavity is elongated together with the bolt. The result is a change in light intensity which can be measured. This means that measuring preload with light is possible. The concept is verified against measurements with a calibrated load cell.

LED lights are becoming increasingly common in our everyday life. This is one of our virtues as we want to make preload data available to the general industry as a means for condition monitoring. Besides being a popular and accessible technology, the ability to measure preload even on small bolt sizes was important. The smallest Strainlabs bolt size is M10 and it measures its own preload with high accuracy, sends the results via ISM Radio to our receiver and still lasts 5 years (room temperature) with our smart battery management system.