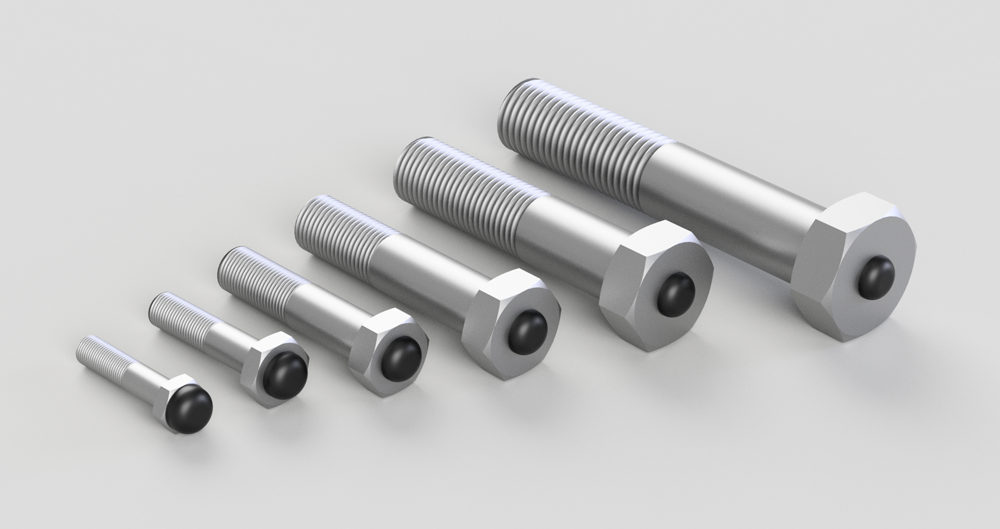

Strainlabs, a leading provider of innovative fastening solutions, announces an expansion of their bolt size range. Previously available in sizes ranging from M10 to M20, the company now introduces three new sizes, M22, M24, and M27, available in property classes 8.8, 10.9 and 12.9 to cater to a broader range of industries and applications.

The decision to introduce the new sizes was driven by customer demand and new market partnerships soon to be announced. “Our customers, especially in industries such as railways and general production, have shown a growing interest in larger bolts, particularly M22-M27. We listened to their needs and initiated the development of this range expansion earlier this year” explains Michael Fransson, Product Manager at Strainlabs.

Strainlabs ambition is to offer high accuracy and precision measurements independent of what bolt size is used. A large load cell has been added to Strainlabs in-house test laboratory for testing and verification of the performance of the new sizes. All bolts undergo rigorous quality and accuracy testing before they are delivered to customers.

“Technically, we were able to use the same sensor as in the smaller sizes, with some minor software adjustments. We have tested the new sizes internally and with external partners and verified that the resolution and capabilities of these new sizes meet our high expectations” continuous Michael Fransson.

Strainlabs scalable IoT invention

One significant advantage of Strainlabs’ sensor technology is its scalability across the M10 to M27 range. By utilizing the same PCB and components, production costs can be reduced as the quantities produced scales up – in spite of the advanced components and high tech included in each individual Strainlabs Bolt. Furthermore, the hardware and software used in the new bolt sizes offer exceptional precision and accuracy, significantly higher compared to commonly used solutions on the market for measuring preload.

Strainlabs plans to continue expanding its bolt size range and make adjustments to accommodate the industry’s need for digitalization of bolted joints independent of application. Csaba Madru, CEO of Strainlabs, explained, “Our current technology has already been tested with even bigger bolts sizes and we have the competence and resources to explore further possibilities should a customer with such needs approach us.”

About Strainlabs

The IndTech company Strainlabs has developed the world’s first CE-market IoT system which utilize bolts with an integrated sensor to automatically monitor machines and applications. The solution is available to digitalize maintenance routines and issue warnings before failures occur. Their complete end-to-end IoT system jacks into existing maintenance routines enables them to remain a leading provider of innovative bolt preload solutions for a wide set of industries.