For Strainlabs IoT bolts to measure the preload in a bolted joint correctly over time, the preload measuring interval and the measuring method must be optimized to provide acceptable battery life catering to industrial needs. In this article we cover the key terminology in battery management and explain how we have optimized product performance.

Battery life factors

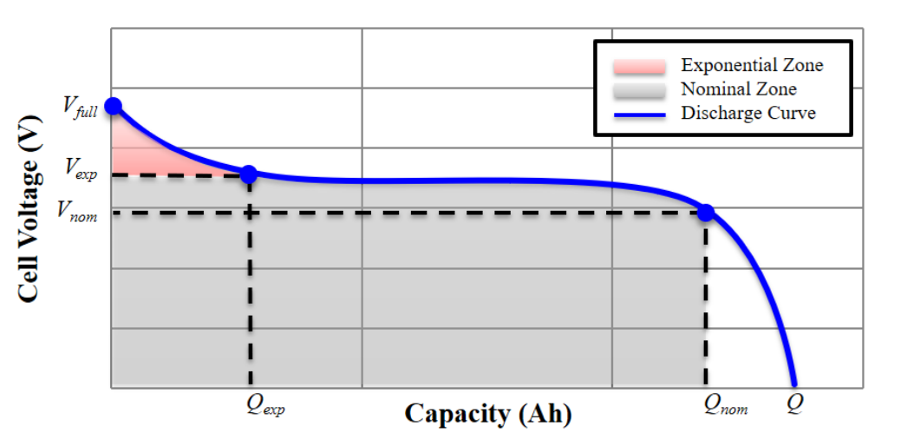

To understand how battery life can be improved it is important to first understand how a battery functions, especially the discharge behavior. It is easy to assume that all batteries have a linear discharge curve i.e., that the voltage drops equally over time, but this is not true for lithium batteries. Lithium batteries are typically used by IoT solutions including Strainlabs.

Ideal discharge curves for a lithium-ion battery. Source: National Renewable Energy Laboratory.

Comparing a lithium battery to a lead-acid battery (which are typically used for car batteries) it is difficult to know from just measuring the voltage what the remaining capacity is in a lithium battery. This is due to the lithium battery having a non-linear behavior in voltage over time. The upside with lithium batteries, however, is that the battery’s power output is more constant than with lead-acid, which provides better overall performance of the system.

Another factor to consider is the self-discharge in batteries which effectively limits the lifetime. The battery type used in the Strainlabs Bolts has a self-discharge of typically 1% per year at 23 degrees Celsius. Very low temperatures will affect the lifetime negatively, which needs to be compensated for.

Strainlabs battery life and performance optimization

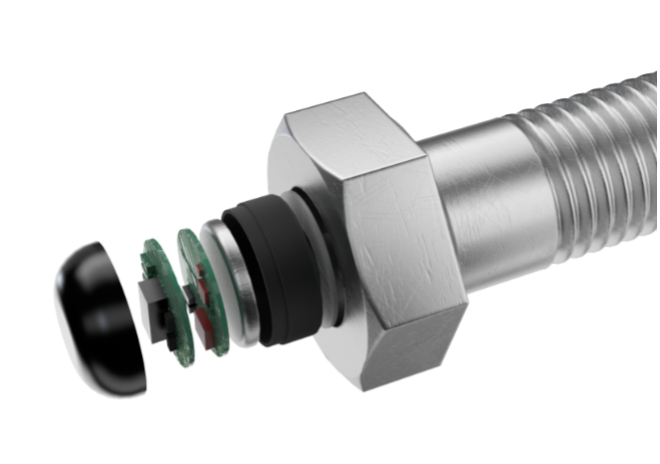

Strainlabs Bolts use a small coin cell battery which is a widely adapted battery used in anything from pacemakers to car keys and other small devices where a traditional battery cannot be used. The small size hinders a high capacity which is why the battery life needs to be optimized. This is achieved in the software by carefully designing the measurement method, radio communication, and transmission frequency.

- Measuring interval: The most obvious factor is setting a reasonable measuring interval. Strainlabs Bolt transmits data for up to 5 years with an interval standardized to 1 packet/10 min to provide sufficient data for preload analysis, but still is seldom enough to allow a long battery lifetime for this type of IoT solution. Strainlabs Bolts are also equipped with a real-time mode for direct feedback during installation, maintenance or R&D tests. Battery life will decline faster if the real-time mode is activated often throughout the lifetime of the Strainlabs Bolt. The measurement interval can be increased and decreased to suit specific application needs and requirements, with obvious changes to the battery life.

- Sleep consumption: Between the measurements, the bolt is put into sleep mode and has a very small consumption in the nA range. Over time the bigger effect is the self-discharge rather than the sleep mode drainage, but both effectively limit total possible lifetime.

- Environmental effects: A factor that might be overlooked is the impact that the environment has on the battery. Cold temperatures greatly impact the overall battery life. To compensate for this, Strainlabs Bolts incorporates a smart battery management system that decreases the transmission frequency as the temperature falls below 0 degrees Celsius, with the longest interval being approximately 3,5 hours. This prolongs the battery life while still giving continuous measurements even in harsh conditions.

- Measurement method: A longer measuring period provides a better and more accurate measuring signal, however it has the drawback of consuming more power. Strainlabs have conducted in-depth research to identify a good industrial “sweet spot” for our IoT Bolts where the measurement window is active for a minimal amount of time, while still providing accurate and precise results.

With these optimizations we can prolong the battery life and performance of Strainlabs Bolts significantly, and at the same time, the bolt can take accurate measurements at a frequency that is far greater than any manual bolt inspection technology.