E-TOTAAL highlights Strainlabs at Hannover Messe 2025

We’re proud to have been featured in the Dutch technology publication e-totaal.nl, which reported from Hannover Messe 2025 – one of the world’s largest industrial

We’re proud to have been featured in the Dutch technology publication e-totaal.nl, which reported from Hannover Messe 2025 – one of the world’s largest industrial

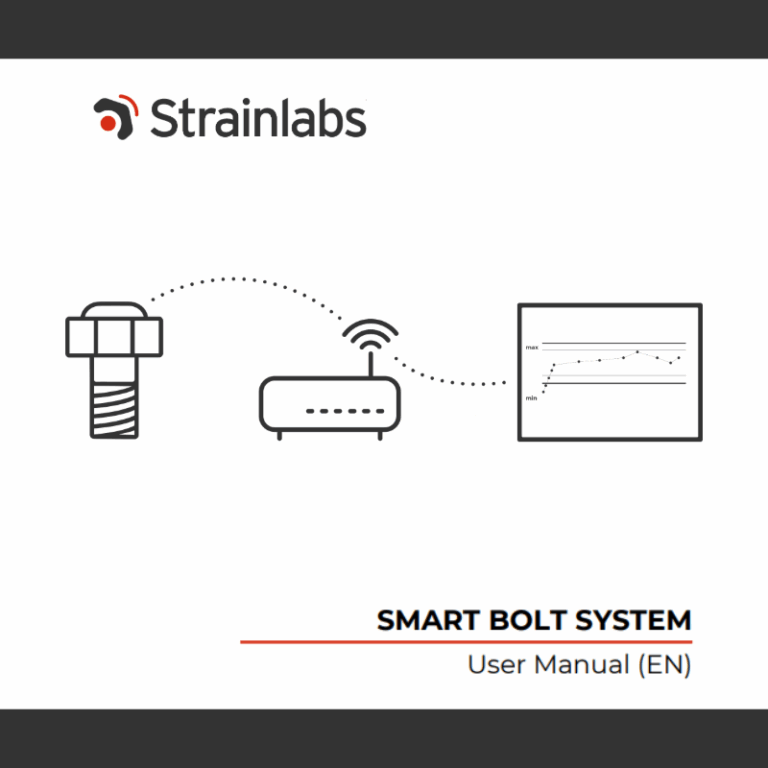

Say Goodbye to guesswork and welcome smart bolt monitoring. Maintaining critical structures has never been easier. Strainlabs eliminates the uncertainty of bolt preload monitoring, giving you insights with a plug-and-play installation. No complex setup, no special tools. From installation to monitoring, the entire process takes minutes – not hours!

At Strainlabs, we’re on a mission to revolutionize industrial maintenance. Bolting is critical across industries, yet traditional predictive maintenance often relies on indirect estimates — such as vibration, temperature, or oil analysis. Strainlabs challenges this norm by delivering direct, actionable data enabling a leap forward in safety, precision, and efficiency.

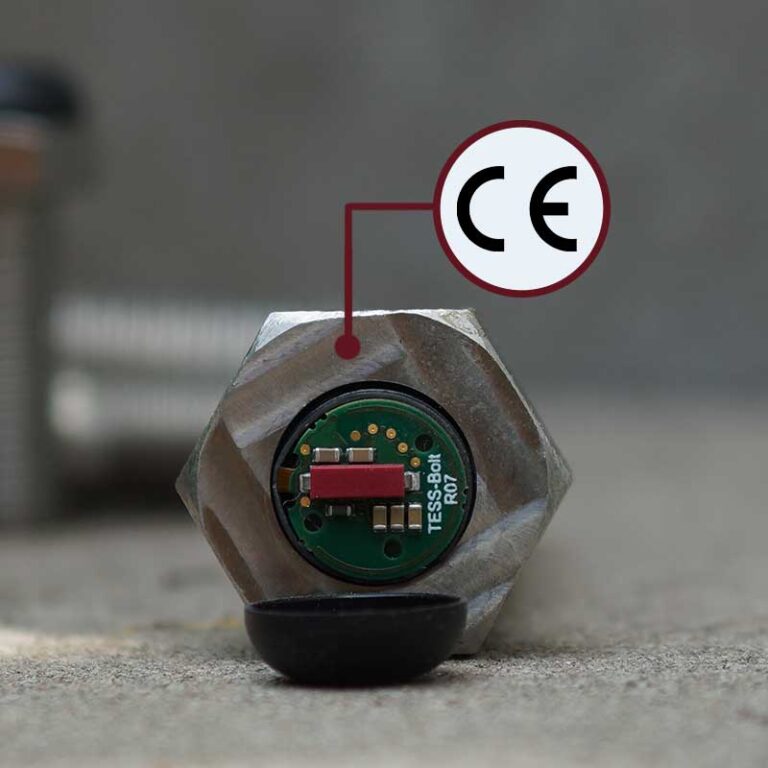

Strainlabs entire system is IP67 rated. We have long been at the forefront of developing a predictive maintenance technology applicable to all industries and thrive under harsh conditions.

Strainlabs’ CE-marked IoT-enabled bolts represent a paradigm shift in industrial bolting technology, revolutionizing the way that maintenance teams monitor and manage bolted connections.

Strainlabs is one of the innovative technologies on a new integration platform developed by Vossloh. The ambition is to transform the railway industry, drive digitization, and bring together data-driven solutions related to railway infrastructure through ‘Vossloh connect’.

Strainlabs Bolt installed on the track of Nyckelpigan rollercoaster at Gröna Lund Amusement park.

We’re excited to announce that we have joined the Railway Cluster of Sweden, bringing our groundbreaking wireless and automated preloading monitoring system to the forefront in the sector. We have also been nominated for the ERCI Innovation Awards, recognizing our relevance and potential in the railway sector.

A main advantage of Strainlabs IoT Bolts is to increase safety and security in the workplace as per target 8.8 in Agenda 2030. Although risks are recognized and accounted for with preventative measures and routines, the total cost of such measures are often not accounted for in cost calculations and maintenance planning.

Daniel Reimhult, a consultant working on advanced measurement systems and data analytics, comments on the key success factors and Strainlabs journey so far in delivering a completely new system to market.

Learn more on how to get started with Strainlabs System